Machining Services

- Tolerances down to ±0.0002″ (0.005mm)

- Lead times from 5 business days

- 28+ surface finishes, 75+ metals & plastics

- ISO 9001:2015 Certified Factory

Our 5-Axis CNC Machining Services

At China Milling, we have state-of-the-art equipment, cutting-edge software, and skilled staff to provide complete 5-sided machining solutions for metal and plastic parts. With our expertise in major CAD/CAM formats, we can seamlessly integrate your design into our machining process. Our multi-axis CNC machining technology allows us to produce parts in complex geometries that other methods cannot. With tolerances within ±0.0005”, you can trust that our products will meet your specifications. We handle projects of all sizes and stay up-to-date with machining technologies to meet your evolving needs. Trust Anebon for exceptional results and reliable service.

Why Choose China Milling 5-axis CNC machining parts?

There are several unique advantages to choosing China Milling for 5-axis machining. Here are some reasons to consider:

5-axis offers many advantages over other manufacturing methods such as 3-axis machining or 3D printing, such as:

- Effective use of floor space

- Excellent anti-collision ability

- Integrated drilling function

- Simple machine setup

- Reduce tool wear and extend the working life

- 5-sided machining for all industries and applications

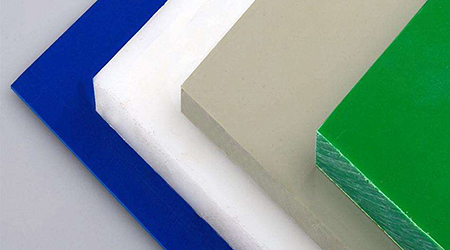

In general, CNC machining processes can handle a wide variety of materials with ease. 5-axis machining processes are no exception. Some typical materials used in 5-axis machining operations include:

Metals

|

|

| Aluminum | |

| Aluminum alloys have a high strength-to-weight ratios, high electrical and thermal conductivity, low density, and natural resistance to corrosion. They can be anodized using a variety of techniques. |

|

|

| Stainless steel | |

| The stainless steel alloys are characterized by their excellent strength, ductility, corrosion and wear resistance. They can be easily joined and machined as well as polished. |

|

|

| Alloy Steel | |

| Alloy steels incorporate additional alloying elements aside from carbon, leading to enhanced qualities such as increased hardness, toughness, fatigue resistance, and wear resistance. |

|

|

| Brass | |

| Brass displays outstanding easiness to machine, favorable ratio of strength to weight, resistance to corrosion, and proficient conduction of electricity and heat. |

|

|

| Copper | |

| Copper, a remarkably malleable metal, finds utility in various applications determined by its mechanical characteristics. It exhibits commendable durability, hardness, exceptional thermal and heat conduction abilities, and corrosion resistance. As a result, it has become a highly sought-after material highly regarded for both its practical functionality and its aesthetic appeal. Furthermore, copper possesses the versatility to be alloyed, thereby enhancing its mechanical attributes. |

|

|

| Titanium | |

| Titanium possesses a variety of material characteristics that designate it as the optimal metal for challenging applications. These traits encompass exceptional resilience against corrosion, chemicals, and extreme temperatures, as well as an exceptional ratio of strength to weight. |

Plastics

|

|

| ABS | |

| ABS, a frequently used thermoplastic, displays favorable mechanical characteristics, outstanding impact resilience, reliable heat tolerance, and commendable machinability. |

|

|

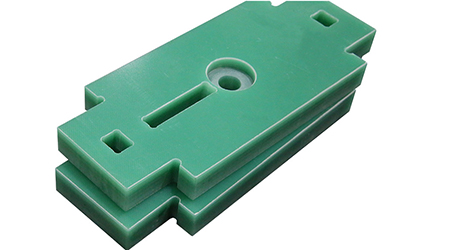

| FR4 | |

| FR4, boasting excellent mechanical strength, superior electrical insulation, and superior machinability, is the ideal choice for electronic applications. |

|

|

| HDPE | |

| HDPE exhibits outstanding resilience to impact, remarkable strength, and impressive machinability, making it well-suited for the production of resilient and sturdy machine components. |

|

|

| PE | |

| PE is characterized by its remarkable impact resistance, exceptional ductility, and minimal friction, which render it an ideal choice for fabricating wear-resistant parts using machining techniques. |

|

|

| PA6 (Nylon) | |

| In machining applications where parts undergo significant mechanical stress, PA6 proves to be an excellent choice due to its combination of high strength, wear resistance, and elasticity. When it comes to machining components that experience substantial mechanical stress, PA6 stands out as an exceptional material option due to its impressive strength, resistance to wear, and elasticity. |

|

|

| PA66 | |

| PA66 displays favorable characteristics like high rigidity, hardness, wear resistance, and thermal dimensional stability. Furthermore, it showcases exceptional wear resistance, low friction, and excellent temperature, chemical, and impact resistance. Nevertheless, caution must be exercised during the processing of PA66 due to its propensity to absorb moisture, which can impact its dimensional stability. |

|

|

| PC | |

| PC, a thermoplastic material, possesses remarkable resilience, exceptional resistance to impacts, and ease of machining. Additionally, it has the capability to exhibit optical transparency. |

|

|

| PEEK | |

| PEEK is characterized by its impressive strength, outstanding ability to withstand high temperatures, and excellent machinability — making it an ideal choice for various high-performance applications. PEEK offers exceptional strength, remarkable thermal resistance, and superior machinability, making it perfectly suited for demanding high-performance uses. |

|

|

| PMMA | |

| PMMA provides remarkable light transmission, impressive mechanical strength, and impeccable machinability, making it a perfect material for optical and aesthetic applications. PMMA exhibits exceptional light transmission, superior strength, and excellent machinability, making it an ideal choice for optical and aesthetic purposes. |

|

|

| POM (Delrin/Acetal) | |

| Precision parts that seek elevated rigidity, minimal friction, and outstanding dimensional stability benefit from the usage of POM, an engineering thermoplastic. |

|

|

| PP | |

| With exceptional fatigue resistance, excellent chemical resistance, and impressive elasticity, PP is perfectly suited for fabricating machined parts that are lightweight and flexible. |

|

|

| PPS | |

| PPS exhibits superb resistance to chemicals, possesses remarkable strength, and demonstrates exceptional machinability; making it an optimal choice for the production of high-performance components. |

|

|

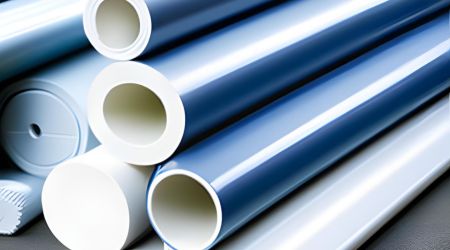

| PVC | |

| Among plastics, PVC stands as the third most widely employed, boasting well-balanced mechanical characteristics, outstanding resistance to chemicals and weather conditions, and notable toughness. |

At China Milling we manufacture components for customers across a wide range of industries.

We offer 5-axis machining services for:

As an ISO9001:2015 certified company, we uphold the highest standards of quality management, ensuring that our precision-engineered parts and products contribute to a healthier and happier future for all.

Learn More >>

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Learn More >>

CNC machining has become a game-changer in automotive manufacturing, revolutionizing the production of critical components with unmatched precision and efficiency. Leveraging Computer Numerical Control (CNC) technology, a wide range of automotive parts can be manufactured to exacting standards, elevating performance and reliability.

Learn More >>

In the dynamic landscape of industrial machinery, Machining-CNC emerges as a distinctive and influential player, contributing significantly to the evolution and optimization of manufacturing processes. Anebon's journey through the realm of precision engineering and cutting-edge solutions has established it as a formidable force in the industrial machinery sector.

Learn More >>

While CNC machining is not typically used to directly fabricate electronic components like integrated circuits or microchips, it can be utilized to produce various mechanical and structural parts that are essential for electronic devices and systems.

Learn More >>

With a commitment to innovation and excellence, Machining-CNC stands as a beacon of progress, actively shaping the future of Robotics & Automation through cutting-edge solutions and CNC machining expertise.

Learn More >>