5 Steps to Launch Small-Scale Maize Milling

29 December 2023

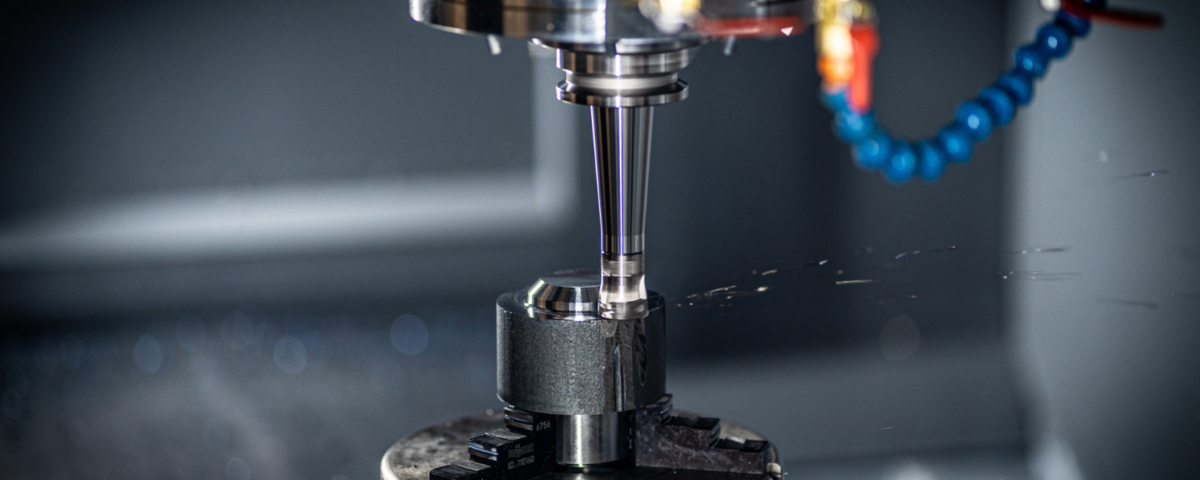

Advantages Of CNC Cutting Machines

4 January 20242 Axis

In the context of CNC (Computer Numerical Control), the 2-axis refers to a system that can move a tool or workpiece in two directions: typically X and Y. This movement allows for cutting, shaping, or milling operations in a two-dimensional plane. While a 2-axis system is limited to movement along two planes, it is commonly used for simpler machining tasks and is an essential component in various CNC applications.

2.5 Axis

In CNC terminology, the 2.5-axis refers to a machining process that involves three-dimensional workpieces but only requires two axes of motion to create the geometry. This typically involves the X and Y axes for horizontal movement and the Z axis for depth. The term "2.5-axis" reflects the capability to move in two primary axes while utilizing partial or limited movement in the third axis, often used for drilling, slotting, and other operations that don't require full 3D movement.

3 Axis

In general, the term 3 axis refers to a three-dimensional coordinate system. It commonly denotes the X, Y, and Z axes, which are used to describe spatial positions in three dimensions. The X-axis typically represents horizontal movement, the Y-axis represents vertical movement, and the Z-axis represents depth or distance. This concept is widely used in fields like mathematics, physics, engineering, and computer graphics to represent spatial relationships and movements.

4 Axis

In various contexts, the 4 axes can refer to different things. In manufacturing, it often denotes a CNC machine capable of movement along the X, Y, Z, and an additional rotational axis (either A or B). In mathematics, a four-dimensional space involves four axes, each perpendicular to the others. In robotics, a 4-axis robot typically refers to a robot with four degrees of freedom for movement. The term can vary based on the specific application or industry.

5 Axis

5 axis cnc machining generally refers to machinery or systems that can move or operate along five different axes. In manufacturing, a 5-axis machine can move along the X, Y, and Z axes, as well as rotate on the A and B axes. This additional freedom allows for more complex and precise machining operations. In other contexts, such as robotics, the term may refer to a system with five degrees of freedom for movement.