Precision Machining Parts: The Backbone of Modern Manufacturing

29 January 2024

Unveiling the Precision and Versatility of Customized Machining Parts

31 January 2024Introduction

Precision machining equipment encompasses a diverse array of machinery designed to fabricate intricate and exacting components with high accuracy. These tools are instrumental in various industries, including aerospace, automotive, electronics, and medical sectors. In this introduction, we'll explore some fundamental types of precision machining equipment, each playing a crucial role in achieving precise and complex part production.

Types of Precision Machining Equipment

1. CNC Machines: Computer Numerical Control (CNC) machines, including mills, lathes, and grinders, are pivotal in precision machining. These automated tools precisely cut and shape materials based on digital designs, ensuring high accuracy and repeatability.

2. Grinding Machines: Utilized for achieving fine surface finishes and tight tolerances, grinding machines employ abrasives to remove material from a workpiece. These are crucial for creating smooth, precise surfaces on various materials.

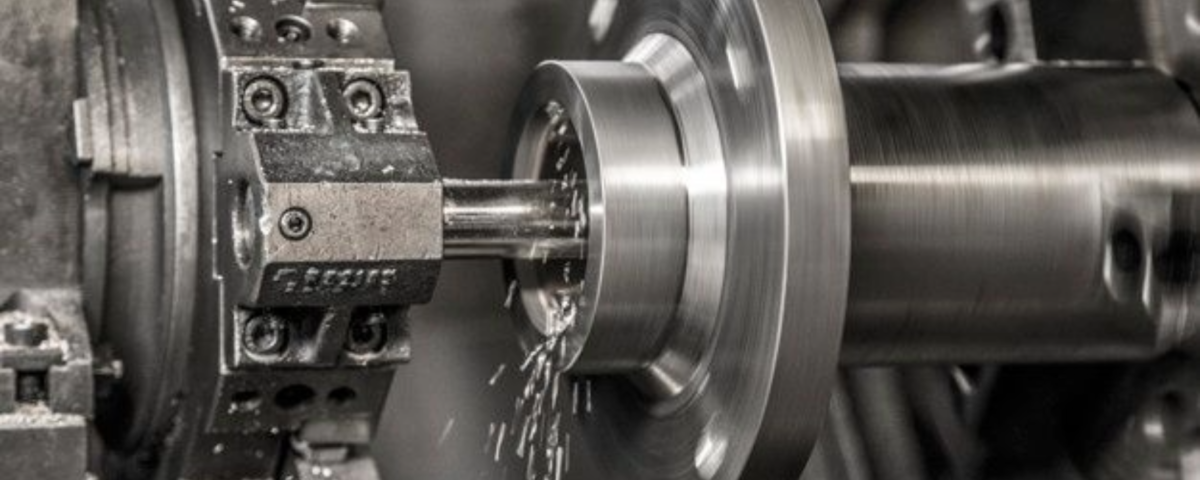

3. Turning Centers: Turning machines, including lathes and turning centers, rotate a workpiece while cutting tools remove material, enabling the production of cylindrical components with exceptional precision.

4. Electrical Discharge Machines (EDM): EDM equipment uses electrical discharges to shape or drill materials that are challenging to machine with traditional tools, allowing for intricate and precise metal removal.

5. Milling Machines: These machines use rotary cutters to remove material from a workpiece, capable of producing an extensive range of complex shapes, slots, and holes with high precision.

6. Laser Cutting Machines: Employing focused laser beams, these machines precisely cut through materials, offering high accuracy and enabling the creation of intricate parts in various thicknesses.

7. Coordinate Measuring Machines (CMM): CMM equipment verifies the dimensional accuracy of machined parts through precise measurement of geometric features, ensuring adherence to design specifications.

These precision machining equipment types represent a foundation for producing intricate parts with high accuracy, catering to the stringent demands of modern manufacturing across diverse industries.

Conclusion

In conclusion, the diverse array of precision machining equipment forms the backbone of modern manufacturing, enabling the creation of intricate components with unparalleled accuracy and efficiency. From CNC machining centers that utilize computer-controlled precision to lathes that shape cylindrical parts with exacting detail, each type of equipment plays a crucial role in meeting the stringent demands of various industries.

Grinding machines provide the fine surface finishes required for precision components, while EDM machines, using electrical discharges or waterjets, excel in tasks that demand intricate shaping and cutting of materials. Coordinate Measuring Machines (CMMs) contribute to quality control by ensuring the precise measurements of manufactured parts, and automatic screw machines streamline high-volume production of small, turned components.