Unleashing the Power of CNC Milling Machines

15 March 2024

The Ultimate Guide to Stainless Steel Parts

22 March 2024Unleashing the Power of Precision: The Artistry and Applications of Custom Metal Stamping

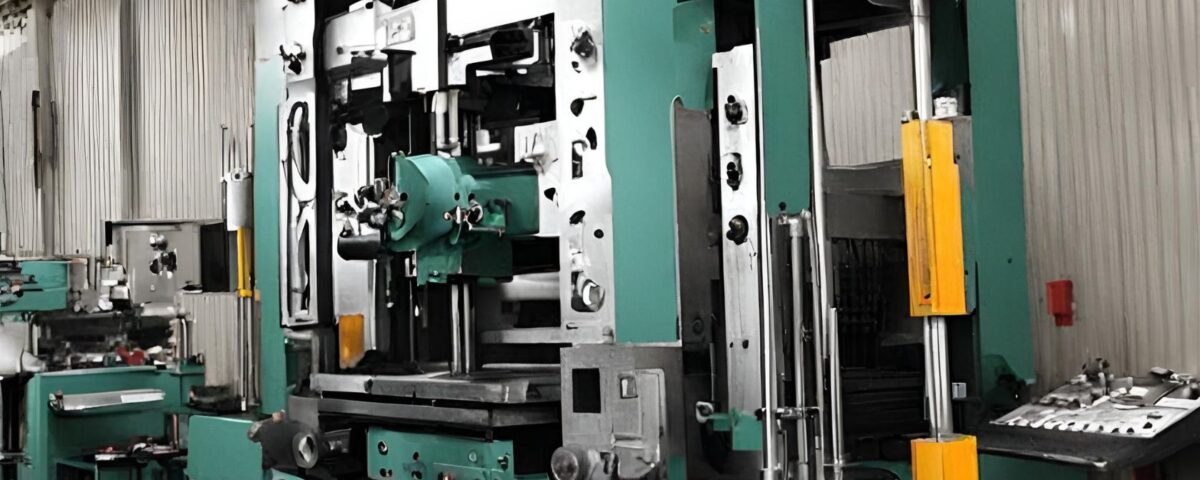

Precision is not just a virtue; it's an art that holds the key to unlocking limitless possibilities. And when it comes to custom metal stamping, precision is the force that propels innovation and revolutionizes industries. From automotive components to aerospace parts, custom metal stamping is a game-changer in the manufacturing world.

With its ability to transform raw materials into customized metal products with unparalleled accuracy and efficiency, custom metal stamping is a force to be reckoned with. And the applications are widespread – from intricate medical devices to robust construction materials, the possibilities are endless.

But precision is not the only weapon in the arsenal of custom metal stamping. With advancements in technology and automation, it has become a vital tool for manufacturers looking to streamline their production processes and reduce costs.

In this article, we will delve into the artistry and applications of custom metal stamping, exploring how it has revolutionized various industries and continues to push the boundaries of what's possible. Get ready to unleash the power of precision and discover the limitless potential of custom metal stamping.

The Artistry Behind Custom Metal Stamping

Custom metal stamping is not just a mechanical process; it's a delicate art that requires skill, precision, and creativity. The process involves using specialized equipment to shape and form metal into intricate designs and patterns. From simple shapes to complex geometries, custom metal stamping can bring any design concept to life.

At the heart of custom metal stamping is the die, a tool that is meticulously crafted to ensure precise and consistent results. The die is created by skilled craftsmen who carefully design and engineer the tool to meet the specific requirements of each project. It's a meticulous process that requires a deep understanding of metallurgy, material properties, and manufacturing techniques.

The artistry of custom metal stamping lies in the ability to transform a flat sheet of metal into a three-dimensional object with incredible precision. Skilled operators use a combination of pressure, heat, and specialized dies to shape the metal into the desired form. It's a delicate dance between man and machine, where every movement is carefully calculated to ensure the perfect outcome.

The artistry of custom metal stamping goes beyond just shaping the metal; it also involves adding intricate details and finishes to the final product. From embossing and engraving to polishing and plating, custom metal stamping can create stunning visual effects that elevate the aesthetics of the finished product.

Custom metal stamping is not just about creating functional parts; it's about creating objects that are a testament to human ingenuity and craftsmanship. It's about pushing the boundaries of what's possible and creating products that are as beautiful as they are functional. The artistry of custom metal stamping is what sets it apart from other manufacturing processes and makes it a truly unique and powerful tool.

Applications of Custom Metal Stamping

The applications of custom metal stamping are vast and diverse, spanning across multiple industries. From automotive and aerospace to medical and electronics, custom metal stamping plays a crucial role in the production of a wide range of products.

In the automotive industry, custom metal stamping is used to manufacture various components, including body panels, brackets, and suspension parts. The precision and efficiency of custom metal stamping make it an ideal choice for high-volume production, allowing automakers to meet the demands of the market while maintaining consistent quality.

In the aerospace industry, custom metal stamping is used to produce critical components that require extreme precision and durability. From engine parts to structural components, custom metal stamping ensures that every piece meets the strict standards required for flight.

The medical industry also benefits greatly from custom metal stamping. From surgical instruments to implantable devices, custom metal stamping enables the production of complex and intricate medical devices with precision and consistency. The ability to create customized designs and sizes allows medical device manufacturers to meet the unique needs of healthcare professionals and patients.

Custom metal stamping is also widely used in the electronics industry. From connectors and terminals to heat sinks and shielding, custom metal stamping ensures that electronic devices function properly and reliably. The ability to produce complex shapes and designs allows electronics manufacturers to create compact and efficient products.

These are just a few examples of the many industries that benefit from custom metal stamping. The versatility and precision of this manufacturing process make it an essential tool for any industry that requires the production of customized metal components.

Advantages of Custom Metal Stamping

The advantages of custom metal stamping are numerous and significant. Here are some of the key benefits that make custom metal stamping a preferred choice for manufacturers:

1. Cost-Efficiency: Custom metal stamping allows for high-volume production at a lower cost compared to other manufacturing methods. The ability to produce multiple parts simultaneously and the efficiency of the process contribute to cost savings.

2. Consistency and Precision: Custom metal stamping ensures consistent and precise results, thanks to the use of specialized dies and automated equipment. This level of precision is crucial for industries that require tight tolerances and strict quality control.

3. Speed and Efficiency: Custom metal stamping is a fast and efficient manufacturing process, allowing for high production rates and quick turnaround times. This is especially beneficial for industries that require rapid production to meet market demands.

4. Design Flexibility: Custom metal stamping offers unparalleled design flexibility, allowing manufacturers to create complex shapes and intricate details. This versatility opens up a world of possibilities and allows for innovative designs.

5. Material Variety: Custom metal stamping can be performed on a wide range of materials, including steel, aluminum, copper, and brass. This versatility allows manufacturers to choose the most suitable material for their specific application, considering factors such as strength, conductivity, and corrosion resistance.

These advantages make custom metal stamping a preferred choice for manufacturers across various industries. The ability to produce high-quality, customized metal components with speed and efficiency is a game-changer in the manufacturing world.

The Precision in Custom Metal Stamping

Precision is at the core of custom metal stamping. The ability to shape and form metal with accuracy and consistency is what sets this manufacturing process apart. But how is precision achieved in custom metal stamping?

One of the key factors that contribute to precision is the quality of the dies used in the process. The dies are carefully engineered to ensure that they can withstand the high pressures and forces involved in metal stamping. They are designed to maintain their shape and integrity even after thousands of stamping cycles, ensuring consistent and precise results.

Another factor that contributes to precision is the use of automated equipment. Advanced technology and robotics have revolutionized custom metal stamping, allowing for precise control of the stamping process. Automated systems ensure that each stamping operation is performed with the same level of accuracy, eliminating human error and variability.

The precision in custom metal stamping also extends to the design and engineering phase. Skilled craftsmen use computer-aided design (CAD) software to create detailed models of the final product. These models are then used to generate the tool paths and instructions for the stamping process, ensuring that every step is meticulously planned and executed.

The combination of high-quality dies, advanced automation, and meticulous planning ensures that custom metal stamping delivers precise and consistent results every time. This level of precision is crucial for industries that require tight tolerances and rely on the integrity of the final product.

Factors to Consider When Choosing a Custom Metal Stamping Supplier

Choosing the right custom metal stamping supplier is essential for the success of your project. Here are some key factors to consider when selecting a supplier:

1. Experience and Expertise: Look for a supplier with a proven track record in custom metal stamping. Experience and expertise are key indicators of quality and reliability.

2. Capabilities and Equipment: Ensure that the supplier has the necessary capabilities and equipment to meet your specific requirements. Consider factors such as the size and capacity of their stamping presses, as well as their ability to handle the materials and finishes you require.

3. Quality Control: Quality is of utmost importance in custom metal stamping. Ask about the supplier's quality control processes and certifications to ensure that they meet the highest standards.

4. Capacity and Lead Times: Consider the supplier's capacity and lead times to ensure that they can meet your production schedule. A supplier with a flexible production capacity and quick turnaround times is preferable.

5. Design and Engineering Support: Look for a supplier that offers design and engineering support to optimize your product design for custom metal stamping. This can help reduce costs, enhance functionality, and improve overall product quality.

6. Cost and Pricing: While cost is an important consideration, it should not be the sole determining factor. Consider the supplier's pricing structure and whether it aligns with the quality and value they offer.

By carefully evaluating these factors, you can find a custom metal stamping supplier that meets your specific needs and ensures the success of your project.

Common Materials Used in Custom Metal Stamping

Custom metal stamping can be performed on a wide range of materials, each with its own unique properties and advantages. Here are some of the most common materials used in custom metal stamping:

1. Steel: Steel is one of the most widely used materials in custom metal stamping due to its strength, durability, and affordability. It is suitable for a wide range of applications and can be easily formed and shaped.

2. Aluminum: Aluminum is a lightweight and corrosion-resistant material that is commonly used in industries such as aerospace and automotive. It offers excellent strength-to-weight ratio and can be easily stamped into complex shapes.

3. Copper: Copper is known for its excellent electrical conductivity and thermal properties. It is often used in the electronics industry for applications such as connectors and terminals.

4. Brass: Brass is a versatile material that offers a unique combination of strength, corrosion resistance, and aesthetics. It is commonly used in applications that require both functionality and visual appeal.

5. Stainless Steel: Stainless steel is known for its exceptional corrosion resistance and hygienic properties. It is commonly used in industries such as food processing, medical, and pharmaceutical.

These are just a few examples of the many materials that can be used in custom metal stamping. The choice of material depends on factors such as the application requirements, desired properties, and budget.

The Process of Custom Metal Stamping

The process of custom metal stamping involves several distinct steps, each crucial in achieving the desired outcome. Here is a simplified overview of the process:

1. Design and Engineering: The process begins with the design and engineering phase, where skilled craftsmen create detailed models and tool paths for the stamping process. This phase ensures that every step is meticulously planned and executed.

2. Material Preparation: The chosen material is prepared by cutting it into sheets or strips of the required size. This ensures that the material is ready for the stamping process.

3. Die Preparation: The die, a specialized tool used in custom metal stamping, is prepared by skilled craftsmen. The die is carefully engineered to ensure precise and consistent results.

4. Stamping Operation: The stamping operation begins with the placement of the material between the die and the stamping press. The press applies pressure to shape and form the material according to the design specifications.

5. Finishing Operations: After the stamping operation, the finished parts undergo various finishing operations, such as deburring, cleaning, and surface treatment. These operations enhance the aesthetics and functionality of the final product.

6. Quality Control: Quality control is an integral part of the custom metal stamping process. The finished parts are thoroughly inspected to ensure that they meet the required specifications and quality standards.

The process of custom metal stamping requires skilled operators, advanced equipment, and meticulous planning. It is a highly efficient and precise manufacturing process that delivers consistent results.

Conclusion: Harnessing the Potential of Custom Metal Stamping

Custom metal stamping is more than just a manufacturing process; it's a powerful tool that unlocks endless possibilities. With its precision, efficiency, and versatility, custom metal stamping has revolutionized various industries and continues to push the boundaries of what's possible.

From automotive and aerospace to medical and electronics, custom metal stamping plays a crucial role in the production of a wide range of products. Its ability to transform raw materials into customized metal components with unparalleled accuracy and efficiency is a game-changer in the manufacturing world.

The artistry behind custom metal stamping lies in the skill and creativity of the craftsmen who meticulously design and engineer the dies. The precision in custom metal stamping is achieved through advanced technology, automation, and meticulous planning.

When choosing a custom metal stamping supplier, factors such as experience, capabilities, and quality control should be considered. The choice of material depends on the specific requirements of the application.

Custom metal stamping is a multi-step process that requires skilled operators, advanced equipment, and