How Aluminium Stamping Revolutionizes Manufacturing Processes

25 April 2024

How to Choose the Right Machining Services

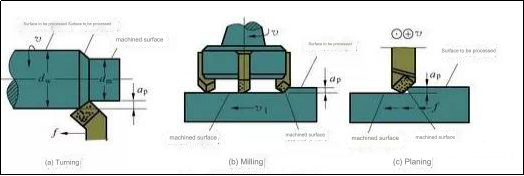

30 April 2024When programming CNC, the programmer must determine the cutting amount for each process and write it into the program in the form of instructions. Cutting usage includes cutting speed, back-cutting amount feed speed, etc. For different processing methods, different cutting amounts need to be selected.

1. Selection principle of cutting amount

During roughing, the primary focus should be on increasing productivity, but it's also important to consider the economy and processing costs. While semi-finishing and finishing, cutting efficiency, economy, processing costs, and processing quality should be taken into account. The specific values should be determined by referring to the machine tool manual, cutting usage manual, and experience.

When selecting the cutting amount, start by determining the amount of back-cutting needed for tool durability. Then, decide on the feed amount and, finally, the cutting speed.

2. Determination of the amount of knife on the back

The amount of back-cutting is determined by the stiffness of the machine tool, workpiece, and tool. If the stiffness allows, it is recommended to make the amount of back-cutting equal to the machining allowance of the mechanical parts as much as possible. By doing so, the number of tool passes can be minimized, and production efficiency can be improved.

Principles for determining the amount of knife on the back:

(1) If the surface roughness value of the workpiece is required to be Ra12.5μm~25μm, then one feed of rough machining can meet the requirements if the machining allowance of CNC machining is less than 5mm~6mm. However, if the margin is large, the rigidity of the processing system is poor, or the power of the machine tool is insufficient, then it may be necessary to complete the machining process in multiple feeds.

(2) When Ra3.2μm~12.5μm surface roughness value is required for the workpiece, it can be achieved through two steps: roughing and semi-finishing. The back-cutting amount selection during rough machining is the same as before. After rough machining, leave a margin of 0.5mm to 1.0mm and remove it during semi-finishing to achieve the desired surface roughness value.

(3) If the desired surface roughness value of a workpiece falls between Ra0.8μm and 3.2μm, it can be achieved through three steps: roughing, semi-finishing, and finishing. The semi-finishing stage requires a back-cutting amount between 1.5 mm and 2 mm. Meanwhile, during the finishing stage, the recommended back-cutting amount is between 0.3 mm to 0.5 mm.

3. Determination of feed amount

The feed rate of a machining process depends largely on the required accuracy and surface roughness of the part being produced, as well as the materials used for the tool and workpiece. The maximum allowable feed rate is determined by the stiffness of the machine tool and the performance of the feed system.

Principles for determining feed speed:

1) When ensuring the cnc machining parts quality requirements, a higher feed speed of 100-200m/min can be selected to enhance production efficiency.

2) When processing deep holes or using high-speed steel tools, it is advisable to choose a lower feed speed, typically within the range of 20-50m/min.

3) When machining accuracy and surface roughness need to be high, a smaller feed speed within the range of 20 to 50m/min is recommended.

4) When the tool is in idle stroke, especially when "returning to zero" at a long distance, you can select the maximum feed speed set by the machine tool CNC system.

4. Determination of spindle speed

The spindle speed should be selected based on the allowed cutting speed and workpiece (or tool) diameter. The calculation formula is:

n=1000v/πD

v----cutting speed, unit is m/min, determined by the durability of the tool;

n---Spindle speed, the unit is r/min;

D---- The workpiece diameter or tool diameter of the unit is mm.

The calculated spindle speed n is finally determined by selecting a speed that the machine tool has or is close to according to the machine tool manual.

To determine the optimal cutting amount, it is important to consider the performance of the machine tool, relevant manuals, and actual experience. The cutting amount should be determined by analogy using these factors. In addition, it is important to ensure that the spindle speed, cutting depth, and feed speed are all optimized in relation to each other.

Reference formula:

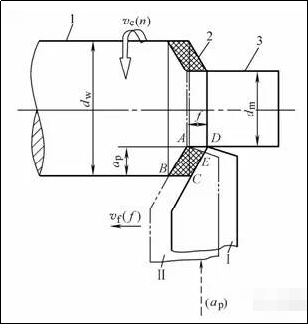

1) Back cutting amount (cutting depth) ap

The distance between the machined surface of the workpiece and the surface to be machined in a vertical direction is referred to as back-cutting amount. The amount of tool engagement measured through the base point of the cutting edge and perpendicular to the working plane is called the back engagement amount. This depth is where the turning tool cuts into the workpiece during each feed, and is also known as the cutting depth. According to this definition, when the outer circle is turned longitudinally, the amount of cutting on the back can be calculated according to the following formula:

a p = ( d w — d m ) /2

In the formula, a p——the amount of knife on the back (mm);

DW——The diameter of the surface to be processed of the workpiece (mm);

dm——The machined surface diameter of the workpiece (mm).

Example 1: It is known that the surface diameter of the workpiece to be processed is Φ95mm; now the diameter is Φ90mm in one feed, and the amount of back cutting is found.

Solution: a p = (d w — d m) /2= (95 —90) /2=2.5mm

2) Feed amount f

The relative displacement of the tool and the workpiece in the direction of feed motion for each revolution of the workpiece or tool.

The feeding direction in a lathe machine can be categorized into two types: longitudinal feed amount and transverse feed amount. Longitudinal feed amount refers to the feed amount in the direction of the lathe bed guide rail, whereas transverse feed amount refers to the feed amount in the direction perpendicular to the lathe bed guide rail. Both types of feed amount are measured in terms of feed rate.

(Note) The feed speed v f refers to the instantaneous speed of the feed movement of the selected point on the cutting edge relative to the mechanical parts.

v f=fn

Where v f——feed speed (mm/s);

n——Spindle speed (r/s);

f——Feed amount (mm/s).

3) Cutting speed v c

The instantaneous velocity of the main motion of a selected point on the cutting edge relative to the workpiece. Calculated as follows

vc=(πdwn)/1000

where v c ——cutting speed (m/min);

dw - diameter of the workpiece surface to be processed (mm);

n——Workpiece rotation speed (r/min).

The calculation should be based on the maximum cutting speed. For example, when turning, the calculation should be based on the diameter of the surface to be machined because the speed is the highest here, and the tool wear is the fastest.

Example 2: Turning the outer circle of a workpiece with a diameter of Φ60mm, the selected lathe spindle speed is 600r/min; find vc.

Solution: v c=( π d w n )/1000 = 3.14x60x600/1000 = 113 m/min

When manufacturing a product, it is common to already know the diameter of the workpiece. Based on factors like the workpiece material, tool material, and processing requirements, the cutting speed is selected. The cutting speed is then converted into the spindle speed of the lathe in order to adjust it accordingly. The following formula is obtained:

n=(1000vc)/πdw

Example 3: Turning the outer circle of the pulley of Φ260mm on the CA6140 horizontal lathe, select vc as 90m/min, and find n.

Solution: n=(1000v c)/ π d w=(1000x90)/ (3.14x260) =110r/min

When selecting the spindle speed for the lathe, it is best to choose a value as close as possible to the nameplate speed. For instance, n=100r/min can be chosen as the actual speed of the lathe.

Summary

cutting amount

1. Back knife amount ap (mm) ap= (dw - dm) / 2 (mm)

2. Feed amount f(mm/r)

3. Cutting speed vc(m/min) Vc=∏dn/1000(m/min)

n=1000vc/∏d(r/min)

Anebon depends on sturdy technical force and continually creates sophisticated technologies to meet the demand for CNC metal machining, 5-axis CNC milling, and casting automobiles. All the opinions and suggestions will be greatly appreciated! The good cooperation could improve both of us into better development!

If you want to know more, please contact [email protected]