The correlation and calculation method of cutting speed, cutting amount and feed speed

26 April 2024

Popular Machining Design Instruments and Manuals

30 April 2024In today's industrial landscape, the demand for precise and efficient machining services is paramount. Whether you're a small business owner or a procurement professional in a large corporation, finding the right machining service provider can significantly impact your bottom line and the quality of your products. With a plethora of options available, selecting the ideal machining service can be a daunting task. However, by considering several key factors, you can streamline the selection process and ensure that you partner with a reliable and capable machining service provider.

Define Your Requirements

When diving into the realm of machining services, clarity regarding your project's requirements is paramount. This clarity not only aids in navigating the vast array of service providers but also ensures that the chosen provider possesses the capabilities necessary to meet your needs. Factors such as material type, part complexity, desired production volume, and specific tolerances must be clearly defined from the outset. By articulating these requirements, you can effectively evaluate potential machining service providers and ascertain their suitability for your project. Whether it's CNC milling for intricate components or precision grinding for surface finishing, aligning your needs with the expertise of the chosen provider is foundational to a successful collaboration.

Furthermore, in the quest for the right machining service, one cannot overlook the significance of quality assurance and certification. In industries where precision and accuracy are non-negotiable, adherence to stringent quality standards is imperative. Therefore, it's essential to prioritize machining service providers with robust quality control processes and relevant certifications such as ISO 9001. These certifications not only underscore a commitment to quality management systems but also instill confidence in the provider's ability to consistently deliver high-quality, precision parts. By prioritizing quality assurance and certification, you can mitigate risks, ensure compliance with industry standards, and ultimately, safeguard the integrity of your projects.

Assess Capabilities and Expertise

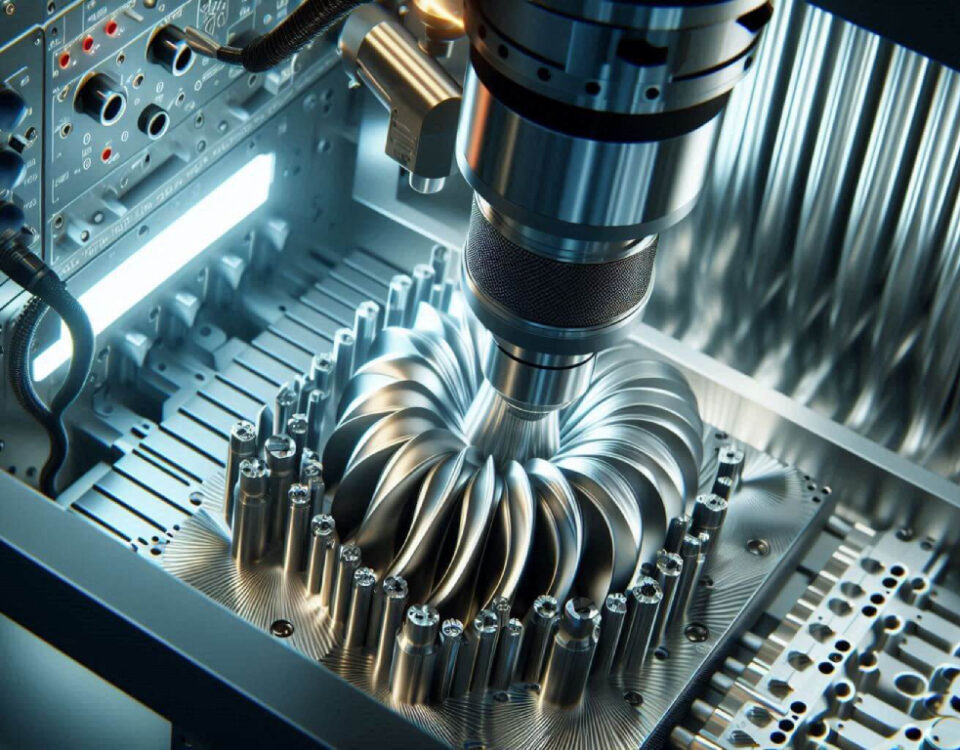

When evaluating potential machining service providers, it's essential to assess their technological capabilities and equipment. The machining industry is continuously evolving, with advancements in CNC automation, multi-axis machining, and high-speed milling revolutionizing production processes. Therefore, partnering with a provider equipped with state-of-the-art machinery and software ensures not only precision and efficiency but also versatility in addressing diverse project requirements. Additionally, inquire about the provider's maintenance practices to ensure that their equipment remains reliable and operational. By aligning your needs with the technological prowess of the chosen provider, you can leverage cutting-edge solutions to optimize production, enhance product quality, and stay ahead of the competition in today's fast-paced industrial landscape.

Quality Assurance and Certification

Quality assurance is paramount in the machining industry, especially for applications where precision and accuracy are critical. When evaluating machining service providers, inquire about their quality control processes, inspection methods, and certifications. Look for providers that adhere to industry standards such as ISO 9001 certification, which demonstrates a commitment to quality management systems. Additionally, inquire about their inspection equipment and capabilities to ensure that they can meet your quality requirements consistently.

Technology and Equipment

| Factors to Consider | Description |

|---|---|

| Quality Assurance | Evaluate the provider's quality control processes, inspection methods, and certifications. |

| Ensure adherence to industry standards such as ISO 9001 for consistent quality management systems. | |

| Inquire about the provider's inspection equipment and capabilities to meet your quality standards. | |

| Technology and Equipment | Assess the provider's machinery and software capabilities, including CNC automation and multi-axis machining. |

| Consider the maintenance practices to ensure reliability and operational efficiency of equipment. | |

| Capacity and Scalability | Evaluate the provider's production capacity, lead times, and flexibility to meet your demand fluctuations. |

| Consider geographic location and logistics capabilities for just-in-time delivery and collaboration. | |

| Cost and Value | Look beyond upfront pricing and assess the overall value proposition, considering quality, expertise, and customer support. |

| Ensure competitive pricing aligns with superior quality, reliability, and service. | |

| Reputation and References | Research the provider's reputation through customer reviews, testimonials, and case studies. |

| Request references from past clients to gauge satisfaction levels and experiences. |

Capacity and Scalability

As your business grows and evolves, your machining needs may change as well. Therefore, it's essential to partner with a machining service provider that can accommodate your current needs while also offering scalability for future projects. Evaluate the provider's production capacity, lead times, and flexibility to ensure that they can meet your demand fluctuations and deadlines effectively. Additionally, consider factors such as geographic location and logistics capabilities, especially if you require just-in-time delivery or proximity for collaboration.

Cost and Value

When weighing the decision of which machining service provider to engage with, the consideration of cost and value emerges as a pivotal factor. While cost is undoubtedly a significant aspect of the equation, it's imperative not to view it in isolation. Instead, a holistic assessment of the overall value proposition should be conducted. Opting for the lowest-priced provider may initially seem financially prudent, yet it could potentially lead to compromises in quality, reliability, or customer service. Therefore, it's essential to strike a balance between cost-effectiveness and the quality of service rendered. By evaluating factors such as expertise, lead times, customer support, and adherence to quality standards, businesses can make informed decisions that optimize value over the long term.

Furthermore, in the pursuit of the right machining service provider, understanding the nuances of cost structures and their implications is paramount. Beyond the upfront price, businesses should delve into the details of what is included in the quoted cost and any potential additional charges that may arise. Transparent communication regarding pricing ensures alignment between expectations and reality, fostering trust and mitigating the risk of unforeseen expenses. Moreover, by considering the broader value proposition encompassing quality, reliability, and customer service, businesses can make strategic investments that yield sustainable returns and drive competitiveness in their respective industries.

Communication and Collaboration

Effective communication and collaboration are essential for a successful partnership with a machining service provider. Look for providers that prioritize communication and are responsive to your inquiries, concerns, and project updates. Additionally, consider their willingness to collaborate closely with your team, providing guidance, insights, and recommendations to optimize your designs and manufacturing processes. A provider that values open communication and collaboration can help streamline production, mitigate risks, and ensure that your project objectives are met effectively.

Customer Support and Service

The level of customer support and service offered by a machining service provider can significantly impact your overall experience and satisfaction. Evaluate the provider's responsiveness, accessibility, and willingness to address any issues or concerns that may arise during the project. Additionally, inquire about their post-production support, such as warranty policies, maintenance services, and ongoing technical assistance. A provider that prioritizes customer support and service demonstrates a commitment to long-term partnerships and customer satisfaction.

Conclusion

In conclusion, choosing the right machining services is a critical decision that can significantly impact the success of your projects and the overall performance of your business. By considering factors such as your project requirements, provider capabilities, quality assurance processes, technology and equipment, scalability, cost and value, reputation, communication, customer support, and cultural fit, you can make an informed decision and select a machining service provider that meets your needs and exceeds your expectations. Remember to conduct thorough research, gather multiple quotes, and ask pertinent questions to ensure that you choose a reliable and capable partner for your machining needs.

Anebon depends on sturdy technical force and continually creates sophisticated technologies to meet the demand for CNC metal machining, 5-axis CNC milling, and casting automobiles. All the opinions and suggestions will be greatly appreciated! The good cooperation could improve both of us into better development!

If you want to know more, please contact [email protected]