Detailed explanation of seven thread processing methods that cannot be missed

8 May 2024

Common accidents and solutions in CNC machining

13 May 2024Unlocking endless possibilities, the art of custom metal fabrication is a testament to human creativity and innovation. From exquisite sculptures to functional architectural masterpieces, custom metal fabrication has the power to transform visions into reality. With precision craftsmanship and meticulous attention to detail, skilled metal fabricators push the boundaries of what can be achieved with this versatile material.

In the realm of creative possibilities, every project is unique. Whether it's a one-of-a-kind furniture piece or a custom-designed signage for a business, the possibilities are limited only by imagination. Working closely with clients, metal fabricators bring their visions to life, infusing artistry and functionality into every project.

Custom metal fabrication is not just about aesthetics; it also offers durability and strength. Metal is a durable material that can withstand the test of time, making it ideal for both indoor and outdoor applications. Additionally, with various types of metals available, such as stainless steel, aluminum, and bronze, custom metal fabrication offers a wide range of options to suit different projects and styles.

The art of custom metal fabrication is a harmonious blend of skill, craftsmanship, and creativity. Through this fascinating process, metal fabricators transform raw materials into timeless works of art, leaving their mark on the world of design and construction.

Advantages of Custom Metal Fabrication

Custom metal fabrication offers a host of advantages that make it a preferred choice for many projects. Firstly, the ability to create one-of-a-kind pieces allows for complete customization, ensuring that the final product perfectly matches the client's vision. This level of personalization sets custom metal fabrication apart from mass-produced items.

In addition, custom metal fabrication offers exceptional durability and strength. Metals such as stainless steel and aluminum are known for their resistance to corrosion and wear, making them suitable for both indoor and outdoor applications. This durability ensures that custom metal fabricated products can withstand the test of time, making them a wise long-term investment.

Furthermore, custom metal fabrication allows for a wide range of design possibilities. Metal can be shaped and manipulated in numerous ways, allowing fabricators to create intricate and complex designs. This flexibility in design opens up a world of creative possibilities, enabling the creation of unique and eye-catching pieces.

Common Applications of Custom Metal Fabrication

Custom metal fabrication finds applications in various industries and sectors. One common application is in the field of architecture. Architects and designers often turn to custom metal fabrication for the creation of unique building facades, decorative elements, staircases, and railings. The ability to customize metal components allows for the integration of both functionality and aesthetic appeal in architectural projects.

Another area where custom metal fabrication shines is in the production of furniture and interior design elements. Metal furniture pieces offer a sleek and modern look, and custom fabrication allows for the creation of unique designs that perfectly fit the desired space. From tables and chairs to custom shelving units and lighting fixtures, metal fabrication adds a touch of elegance and sophistication to any interior.

Custom metal fabrication is also widely used in the automotive and aerospace industries. From custom engine parts to aircraft components, metal fabrication plays a crucial role in ensuring the reliability and performance of vehicles and aircraft. The precision and durability offered by metal fabrication methods make them an essential part of the manufacturing process in these industries.

Materials Used in Custom Metal Fabrication

A wide range of metals can be used in custom metal fabrication, each with its own unique properties and characteristics. One commonly used metal is stainless steel. Known for its corrosion resistance and strength, stainless steel is a popular choice for applications that require both durability and aesthetic appeal. Its sleek and polished appearance makes it a versatile material for various projects.

Aluminum is another commonly used metal in custom metal fabrication. Lightweight yet strong, aluminum is ideal for applications that require structural integrity without adding excessive weight. It is commonly used in the aerospace industry, as well as in the production of automotive parts and furniture.

Bronze is a metal that has been used for centuries in art and sculpture. With its warm, golden hue, bronze adds a touch of elegance and sophistication to any project. It is a durable and malleable material that allows for intricate detailing and fine craftsmanship. Bronze is often chosen for sculptures, decorative elements, and architectural accents.

Steps Involved in the Custom Metal Fabrication Process

The custom metal fabrication process typically involves several steps, each contributing to the creation of a final product that meets the client's specifications. The first step is the design phase, where the client's vision is translated into a detailed design plan. This may involve sketches, computer-aided design (CAD) software, or physical prototypes.

Once the design is finalized, the next step is material selection. Based on the project requirements and desired aesthetics, the appropriate metal is chosen. This step also involves considering factors such as durability, strength, and corrosion resistance.

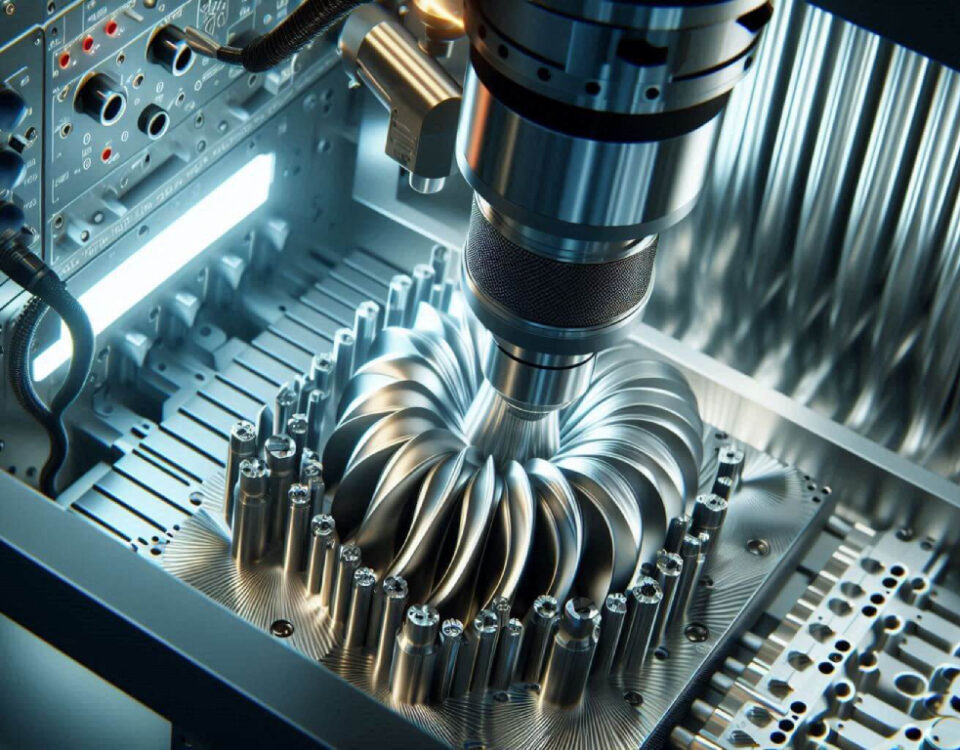

After material selection, the fabrication process begins. This typically involves cutting the metal into the desired shapes and sizes using tools such as laser cutters, plasma cutters, or water jet cutters. The next step is forming, where the metal is shaped and bent to achieve the desired design. Techniques such as bending, rolling, and welding are used to create complex shapes and structures.

Once the metal has been formed, the next step is surface finishing. This may involve processes such as polishing, grinding, or sandblasting to achieve the desired texture and appearance. Surface finishes can range from smooth and reflective to matte or textured, depending on the desired aesthetic.

The final step in the custom metal fabrication process is assembly. This involves joining the different metal components together using techniques such as welding, bolting, or riveting. The assembly process ensures that the final product is structurally sound and meets the client's specifications.

Techniques and Tools Used in Custom Metal Fabrication

Custom metal fabrication employs a variety of techniques and tools to shape and manipulate metal. One commonly used technique is welding. Welding involves joining two or more metal pieces together by melting the edges and allowing them to fuse. Different types of welding methods, such as MIG welding, TIG welding, and arc welding, are used depending on the specific project requirements.

Cutting is another essential technique in metal fabrication. Various cutting methods, such as laser cutting, plasma cutting, and water jet cutting, allow fabricators to accurately and precisely cut metal into desired shapes and sizes. These cutting methods offer different levels of precision, speed, and versatility, depending on the project requirements.

Forming and bending are techniques used to shape metal into desired forms. Press brakes, rollers, and bending machines are commonly used tools in custom metal fabrication to achieve precise bends and curves. These techniques are crucial in creating complex and intricate designs, such as architectural elements or sculptures.

Surface finishing techniques are used to enhance the appearance and texture of metal. Polishing, grinding, sandblasting, and chemical treatments are some of the methods employed to achieve desired surface finishes. These techniques can create smooth, reflective surfaces or add texture and depth to the metal.

Custom Metal Fabrication vs. Standard Fabrication Methods

Custom metal fabrication differs from standard fabrication methods in several ways. Standard fabrication methods typically involve mass production and the use of pre-designed templates or molds. This limits the flexibility and customization options available to the client. On the other hand, custom metal fabrication allows for complete personalization and the creation of unique pieces tailored to specific requirements.

In terms of design, standard fabrication methods often prioritize efficiency and cost-effectiveness over creativity and aesthetics. Custom metal fabrication, on the other hand, places a strong emphasis on design and craftsmanship, allowing for the creation of visually stunning and intricate pieces.

Standard fabrication methods also tend to use lower-quality materials and production techniques to keep costs down. Custom metal fabrication, in contrast, offers a wider range of high-quality materials and production methods, ensuring the durability and longevity of the final product.

Factors to Consider When Choosing a Custom Metal Fabrication Service

When selecting a custom metal fabrication service, several factors should be considered to ensure the best possible outcome. Firstly, it is essential to evaluate the expertise and experience of the fabricator. Look for a company or individual with a proven track record of delivering high-quality projects and who has experience working on projects similar to the one at hand.

Communication is another crucial factor. A good fabricator should be able to understand and interpret the client's vision accurately. They should be able to provide clear and timely communication throughout the fabrication process, keeping the client informed and involved every step of the way.

Quality assurance is also paramount. Ask about the fabricator's quality control processes and ensure that they have rigorous standards in place to ensure that the final product meets or exceeds expectations.

Finally, consider the overall cost and timeline. While it is essential to stay within budget and meet deadlines, it is equally important not to compromise on quality. Look for a fabricator who can provide a balance between cost, quality, and timely delivery.

Examples of Unique and Creative Custom Metal Fabrication Projects

Custom metal fabrication has been used to create numerous unique and creative projects. One such example is the Cloud Gate sculpture, also known as "The Bean," located in Chicago's Millennium Park. Designed by artist Anish Kapoor, this iconic sculpture is made of highly polished stainless steel, reflecting the city's skyline and creating an otherworldly visual experience.

In the field of architecture, the Sydney Opera House stands as a testament to the endless possibilities of custom metal fabrication. The unique sail-like design of the building's exterior was made possible through the use of custom-fabricated metal components. This iconic structure has become a symbol of Sydney and a globally recognized architectural masterpiece.

Another example of custom metal fabrication pushing the boundaries of design is the Guggenheim Museum in Bilbao, Spain. Designed by architect Frank Gehry, the museum's titanium-clad exterior is a stunning example of how metal fabrication can be used to create dynamic and visually striking structures.

Conclusion: Embracing the Limitless Potential of Custom Metal Fabrication

Custom metal fabrication is an art form that unlocks endless possibilities. From architectural marvels to unique furniture pieces and stunning sculptures, custom metal fabrication allows for the creation of one-of-a-kind masterpieces that blend artistry and functionality. With a wide range of materials, techniques, and tools available, the only limit is the imagination.

The advantages of custom metal fabrication, such as durability, strength, and design flexibility, make it a preferred choice for many projects across various industries. Whether it's creating a custom building facade, a unique furniture piece, or a decorative sculpture, custom metal fabrication offers the opportunity to bring visions to life and leave a lasting mark on the world of design and construction.

By choosing a reputable custom metal fabrication service and considering factors such as expertise, communication, quality assurance, and cost, clients can ensure that their projects are executed with precision and excellence. Embracing the limitless potential of custom metal fabrication opens up a world of creative possibilities, where imagination knows no bounds. So, let your imagination run wild and unlock the endless possibilities of custom metal fabrication.