For Rapid Prototyping

And Production.

4 Axis And 5 Axis CNC Machines.

- Tolerances down to ±0.0002″ (0.005mm)

- Lead times from 5 business days

- 28+ surface finishes, 75+ metals & plastics

- ISO 9001:2015 Certified Factory

Our CNC Machining Services

Do you need a reliable partner for CNC machining?

China Milling offers a wide range of custom CNC machining online services, including milling and turning, EDM and surface grinding. Our precision 3-axis, 4-axis, and 5-axis CNC machines, along with our advanced capabilities and experienced team can handle any type of CNC machining part in metal or plastic. Our online CNC machining services are the best option for prototypes and production parts.

|

| CNC Turning Service |

| CNC turning is a subtractive machining process in which a metal bar or rod is rotated at a high speed while a cutting tool removes material from it. By combining multiple axes of movement and cutting tools and rotating the raw material at a high rate speed, we can achieve an almost infinite number of design features for your parts. It can be done alone or in conjunction with other machining processes like milling to achieve more complex shapes |

|

| CNC Milling Service |

| CNC Milling and Machining is a subtractive machining process that uses computer-controlled tools that utilize bits such as ball end mills, flat end mills, and single flutes to remove material from a solid block of material.3 Axis, 4 Axis, and 5 Axis CNC Machining Services for simple and complex geometrical parts. |

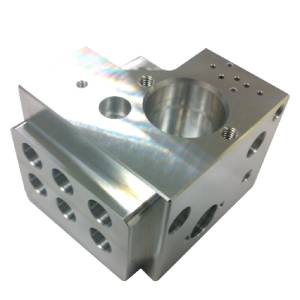

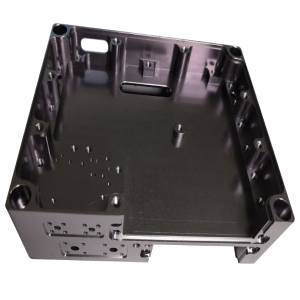

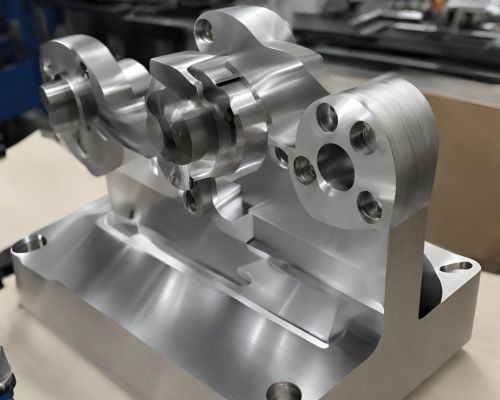

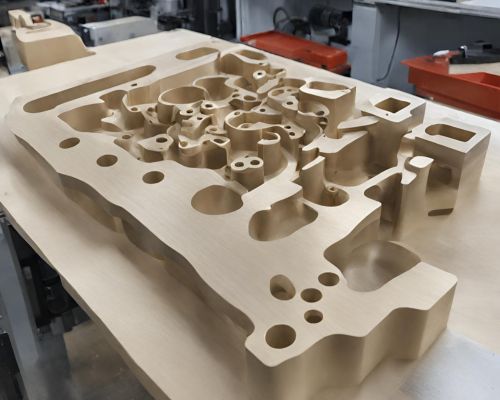

We put the product photos customized for customers from various countries into the Gallery,

We hope that through the pictures of parts in the Gallery, all customers can understand our CNC machining capabilities more intuitively.

China Milling's team will try its best to use all existing resources to help customers produce ideal parts at the best price.

So, if you are looking for a reliable CNC manufacturer for your project, you have found it.

How China Milling Works

China Milling provides complete high-precision CNC machining services to customers in Europe, America, Australia, Japan and South Korea. From prototyping to small numbers of test pieces to mass production running in the tens of thousands, we are your number one source for high quality, competitively priced metalworking services.

With our precise CNC machining capabilities, China Milling stands as your perfect collaborator in the production of accurate prototypes and parts. Our CNC machining adheres to ISO 2768-f standards for metals and ISO 2768-m standards for plastics, guaranteeing accuracy and quality. Moreover, we are fully capable of meeting any specific tolerances you may require, provided that you clearly outline your specifications on the drawing.

| Standards | CNC Milling | CNC Turning |

|---|---|---|

| Maximum Part Size | 3800×1300×500 mm | 180×450 mm |

| 149.6×51.8×19.7 in. | 7.1×17.7 in. | |

| Minimum Part Size | 4×4 mm | 2×2 mm |

| 0.1×0.1 in. | 0.079×0.079 in. | |

| Minimum Feature Size | Φ 0.40 mm | Φ 0.40 mm |

| Φ 0.016 in. | Φ 0.016 in. | |

| Standard Tolerances | Metals: ISO 2768-f | Metals: ISO 2768-f |

| Plastics: ISO 2768-m | Plastics: ISO 2768-m | |

| Linear Dimension | +/- 0.01 mm | +/- 0.01 mm |

| +/- 0.0004 in. | +/- 0.0004 in. | |

| Hole Diameters | +/- 0.02 mm | +/- 0.02 mm |

| (Not Reamed) | +/- 0.0008 in. | +/- 0.0008 in. |

| Shaft Diameters | +/- 0.02 mm | +/- 0.02 mm |

| +/- 0.0008 in. | +/- 0.0008 in. | |

| Edge Condition | Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing | |

| Threads and Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter | Diameter: Φ 1.5-5 mm, depth: 3×diameter |

| Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 5 mm or more, depth: 4-6×diameter | |

| China Milling can produce threads of any specification and size required by our customers. | ||

| Text | Minimum width of 0.5 mm, depth of 0.1 mm | China Milling can use laser marking to create standard text for CNC turned parts. |

| China Milling can use CNC engraving or laser carving to create standard text based on customers’ requiremnts. | China Milling can use CNC engraving or laser carving to create standard text based on customers’ requiremnts. | |

| Lead Time | 5 business days | 5 business days |

Metals

|

| Aluminum |

| Aluminum alloys have a high strength-to-weight ratios, high electrical and thermal conductivity, low density, and natural resistance to corrosion. They can be anodized using a variety of techniques. |

|

| Stainless Steel |

| The stainless steel alloys are characterized by their excellent strength, ductility, corrosion and wear resistance. They can be easily joined and machined as well as polished. |

|

| Alloy steel |

| Alloy steels incorporate additional alloying elements aside from carbon, leading to enhanced qualities such as increased hardness, toughness, fatigue resistance, and wear resistance. |

|

| Brass |

| Brass displays outstanding easiness to machine, favorable ratio of strength to weight, resistance to corrosion, and proficient conduction of electricity and heat. |

|

| Copper |

| Copper, a remarkably malleable metal, finds utility in various applications determined by its mechanical characteristics. It exhibits commendable durability, hardness, exceptional thermal and heat conduction abilities, and corrosion resistance. As a result, it has become a highly sought-after material highly regarded for both its practical functionality and its aesthetic appeal. Furthermore, copper possesses the versatility to be alloyed, thereby enhancing its mechanical attributes. |

|

| Titanium |

| Titanium possesses a variety of material characteristics that designate it as the optimal metal for challenging applications. These traits encompass exceptional resilience against corrosion, chemicals, and extreme temperatures, as well as an exceptional ratio of strength to weight. |

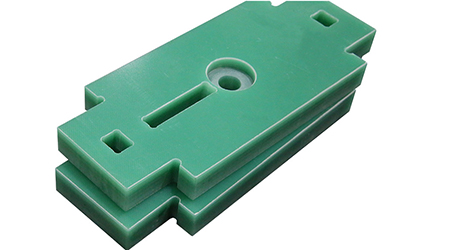

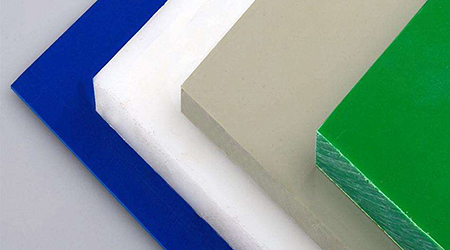

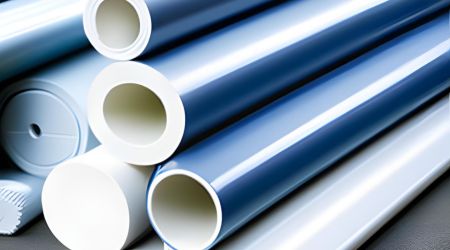

Plastics

|

| ABS |

| ABS, a frequently used thermoplastic, displays favorable mechanical characteristics, outstanding impact resilience, reliable heat tolerance, and commendable machinability. |

|

| FR4 |

| FR4, boasting excellent mechanical strength, superior electrical insulation, and superior machinability, is the ideal choice for electronic applications. |

|

| HDPE |

| HDPE exhibits outstanding resilience to impact, remarkable strength, and impressive machinability, making it well-suited for the production of resilient and sturdy machine components. |

|

| PE |

| PE is characterized by its remarkable impact resistance, exceptional ductility, and minimal friction, which render it an ideal choice for fabricating wear-resistant parts using machining techniques. |

|

| PA6 (Nylon) |

| In machining applications where parts undergo significant mechanical stress, PA6 proves to be an excellent choice due to its combination of high strength, wear resistance, and elasticity.When it comes to machining components that experience substantial mechanical stress, PA6 stands out as an exceptional material option due to its impressive strength, resistance to wear, and elasticity. |

|

| PA66 (Nylon) |

| PA66 displays favorable characteristics like high rigidity, hardness, wear resistance, and thermal dimensional stability. Furthermore, it showcases exceptional wear resistance, low friction, and excellent temperature, chemical, and impact resistance. Nevertheless, caution must be exercised during the processing of PA66 due to its propensity to absorb moisture, which can impact its dimensional stability. |

|

| PC |

| PC, a thermoplastic material, possesses remarkable resilience, exceptional resistance to impacts, and ease of machining. Additionally, it has the capability to exhibit optical transparency. |

|

| PEEK |

| PEEK is characterized by its impressive strength, outstanding ability to withstand high temperatures, and excellent machinability — making it an ideal choice for various high-performance applications. PEEK offers exceptional strength, remarkable thermal resistance, and superior machinability, making it perfectly suited for demanding high-performance uses. |

|

| PMMA |

| PMMA provides remarkable light transmission, impressive mechanical strength, and impeccable machinability, making it a perfect material for optical and aesthetic applications. PMMA exhibits exceptional light transmission, superior strength, and excellent machinability, making it an ideal choice for optical and aesthetic purposes. |

|

| POM (Delrin/Acetal) |

| Precision parts that seek elevated rigidity, minimal friction, and outstanding dimensional stability benefit from the usage of POM, an engineering thermoplastic. |

|

| PP |

| With exceptional fatigue resistance, excellent chemical resistance, and impressive elasticity, PP is perfectly suited for fabricating machined parts that are lightweight and flexible. |

|

| PPS |

| PPS exhibits superb resistance to chemicals, possesses remarkable strength, and demonstrates exceptional machinability; making it an optimal choice for the production of high-performance components. |

|

| PVC |

| Among plastics, PVC stands as the third most widely employed, boasting well-balanced mechanical characteristics, outstanding resistance to chemicals and weather conditions, and notable toughness. |

Others Materials

|

| Carbon Fiber |

| When it comes to machining, carbon fiber, also known as graphite fiber, emerges as a top contender due to its remarkable strength and lightweight nature. Outperforming steel with its five-fold strength and double the stiffness, carbon fiber is a sought-after material in the machining industry. |

|

| Wood |

| Natural aesthetic appeal: Wood offers a warm and visually pleasing appearance, adding a natural charm to products. Versatility: Wood can be easily shaped and carved using CNC machines, allowing for intricate designs and customization. Sustainability: Wood is a renewable resource, making it an environmentally-friendly choice for CNC processed products. Cost-effectiveness: Compared to other raw materials, wood can be relatively affordable, making it a cost-effective option for production. Durability: With proper maintenance and treatment, wood can have good resistance to wear, tear, and impact. |

CNC Machining Surface Treatment

Rapid Prototyping

From China Milling, you can get your prototypes done in days, which allows you to verify the design fast.

![]() Instant quotes

Instant quotes

![]() Instant DFM feedback

Instant DFM feedback

![]() Top quality

Top quality

![]() Fast delivery

Fast delivery

Small Batch Production

Rapid tooling serves as a cost-effective method for seamlessly transitioning from prototyping to full-scale production, enabling swift market launches for your products.

![]() Cost-Efficiency

Cost-Efficiency

![]() Production-level quality

Production-level quality

![]() Evaluate market viability prior.

Evaluate market viability prior.

Customized Production

For production projects, our engineering team will collaborate with you to optimize product quality and cost-effectiveness.

![]() Flexible

Flexible

![]() Efficient

Efficient

![]() Customized

Customized

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Learn More >>

As an ISO9001:2015 certified company, we uphold the highest standards of quality management, ensuring that our precision-engineered parts and products contribute to a healthier and happier future for all.

Learn More >>

CNC machining has become a game-changer in automotive manufacturing, revolutionizing the production of critical components with unmatched precision and efficiency. Leveraging Computer Numerical Control (CNC) technology, a wide range of automotive parts can be manufactured to exacting standards, elevating performance and reliability.

Learn More >>

In the dynamic landscape of industrial machinery, Machining-CNC emerges as a distinctive and influential player, contributing significantly to the evolution and optimization of manufacturing processes. Machining-CNC's journey through the realm of precision engineering and cutting-edge solutions has established it as a formidable force in the industrial machinery sector.

Learn More >>

While CNC machining is not typically used to directly fabricate electronic components like integrated circuits or microchips, it can be utilized to produce various mechanical and structural parts that are essential for electronic devices and systems.

Learn More >>

With a commitment to innovation and excellence, Machning-CNC stands as a beacon of progress, actively shaping the future of Robotics & Automation through cutting-edge solutions and CNC machining expertise.

Learn More >>