Understanding the Drilling Operations in CNC Manufacturing

6 November 2024

How Rapid Prototyping Accelerates Innovation Across Industries

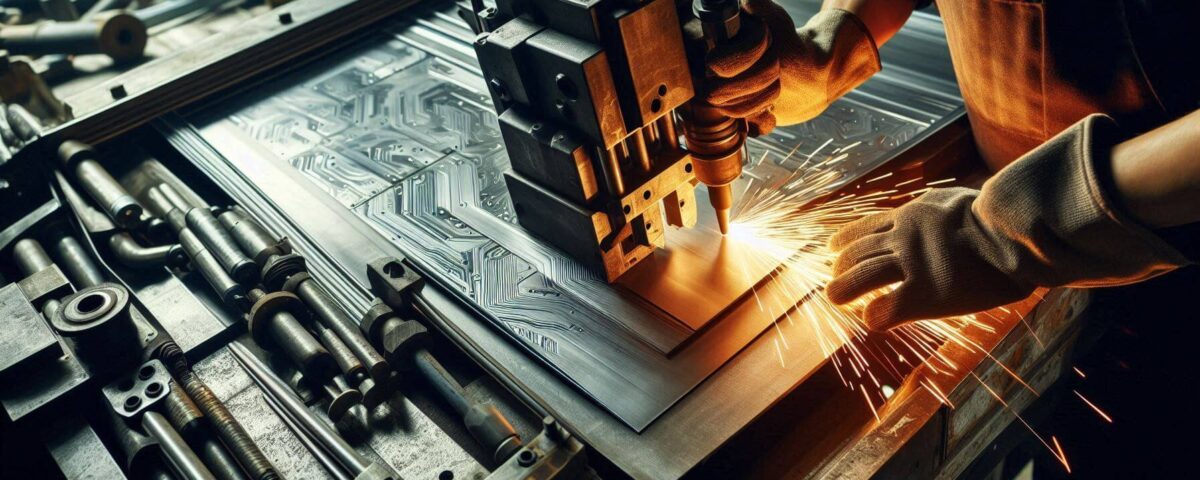

14 November 2024One of the most important procedures in contemporary manufacturing is sheet metal fabrication, which shapes the sectors on which we depend on a daily basis. Sheet metal fabrication is essential to the production of components and goods that drive our economy in a variety of industries, including electronics, automotive, and aerospace. Thin metal sheets are cut, bent, and assembled into final products using this flexible manufacturing technique, which enables accuracy, robustness, and longevity. Here is a closer look at the ways that sheet metal fabrication affects and molds contemporary businesses.

How Sheet Metal Fabrication Shapes Modern Industries

Sheet metal fabrication plays a pivotal role across many sectors, driving innovation, improving efficiency, and creating durable products. Here’s a breakdown of how this essential manufacturing process shapes modern industries.

1. Key Applications in Automotive Manufacturing

Sheet metal manufacturing is essential to the automobile sector. Sheet metal is a key component utilized in the manufacture of automobiles, from the body panels to interior parts including exhaust systems, brackets, and chassis pieces. Parts that must endure high stresses and extremely high temperatures are precisely shaped because to this method.

Manufacturers can now create high-quality, lightweight, and long-lasting sheet metal components that improve vehicle performance and fuel economy thanks to technological breakthroughs like robotic welding and CNC (Computer Numerical Control) machinery. Because sheet metal fabrication can create intricate shapes and designs, automakers have been able to develop and produce automobiles that are both aesthetically beautiful and structurally sound.

2. Revolutionizing the Aerospace Industry

Reliability and accuracy are essential in the aircraft sector. The production of airplane parts like wings, fuselages, and engine sections depends heavily on sheet metal fabrication. Because sheet metal is strong and lightweight, it can be used to create sections that can withstand flight stresses while maintaining a tolerable aircraft weight.

Modern aircraft require parts with complex geometry and precise tolerances, which aerospace manufacturers can provide thanks to advanced fabrication techniques like waterjet and laser cutting. Additionally, the durability and safety of components used in aerospace applications are guaranteed by sheet metal's capacity to be treated for resistance to corrosion and high temperatures.

3. Construction and Architecture: Shaping the Modern Skyline

The architectural and construction sectors are also greatly impacted by sheet metal fabrication. Because of its strength, flexibility, and aesthetic appeal, sheet metal is used extensively in everything from siding and roofing to structural elements like beams, columns, and panels. For instance, metal roofing is growing in popularity in both residential and commercial buildings because of its resilience to harsh weather conditions, energy efficiency, and longevity.

Metal panels are frequently utilized in architecture for external facades because they offer both long-lasting weather protection and contemporary aesthetics. Because sheet metal fabrication enables the creation of unique shapes and finishes, it has emerged as the preferred material for architects seeking to combine aesthetic appeal with practicality.

4. Electronics and Consumer Goods

Sheet metal manufacturing is necessary for many consumer electronics items, such as computers, smartphones, and household appliances. Thin, robust metal sheets are frequently used to create the housing and interior parts of these goods, giving them structural robustness and a sleek appearance.

In the electronics sector, where even the smallest tolerances are essential for operation, sheet metal manufacturing precision is especially critical. For instance, metal components are utilized in computer and phone casings, enclosures, and heat sinks to help control temperature and shield delicate inside bits. Furthermore, consistency and dependability in consumer goods are guaranteed by the high precision mass production of these components.

5. Energy and Renewable Industries

Additionally, sheet metal manufacturing is essential to the energy sector, which includes both the conventional power generation and renewable energy sectors. Sheet metal is utilized in power plants to construct parts such as piping systems, heat exchangers, and ventilation ducts. For these metal components to remain effective and safe, they must withstand extreme temperatures and pressures.

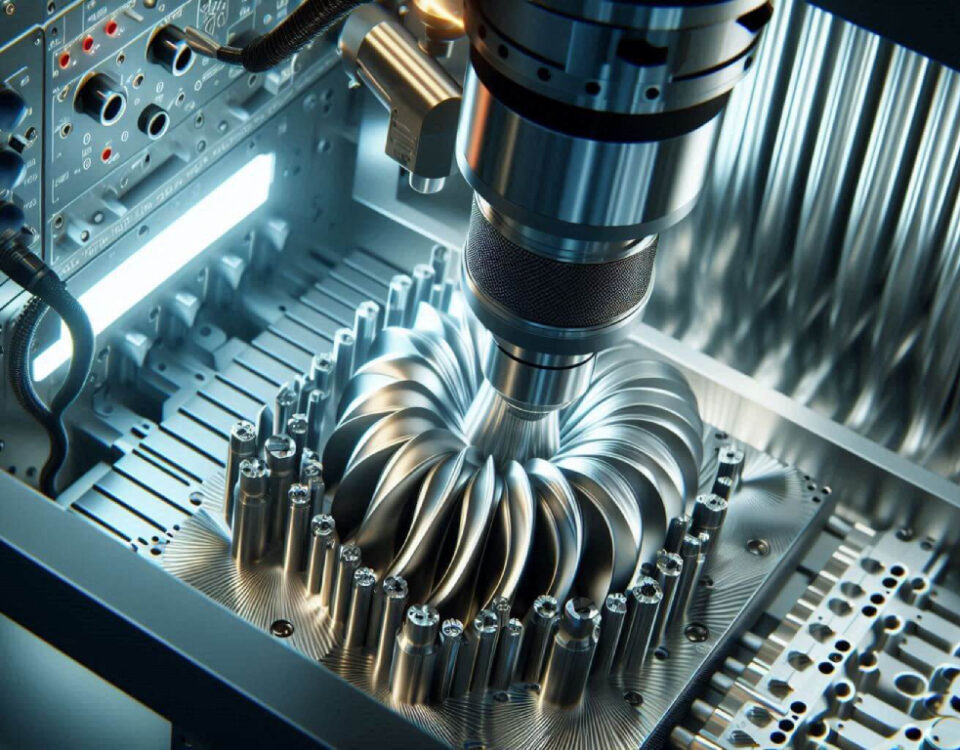

6. Innovation in Manufacturing and Prototyping

Manufacturers can rapidly develop prototypes, test designs, and refine concepts because to the process's versatility. Industries like product design and production, where speed to market is crucial, have been completely transformed by this capacity to prototype and build parts quickly.

Furthermore, sheet metal fabrication is now much more accurate and efficient because to the use of automated technology like robotics and 3D laser cutting. This technical development lowers errors and material waste while simultaneously increasing production and improving product quality and uniformity. Complex, high-performance items may now be produced by industries faster and more cheaply than ever before.

7. Sustainability and Recycling

As industries seek to become more sustainable, sheet metal fabrication offers significant advantages. Many sheet metals are made from recyclable materials, and the fabrication process itself generates minimal waste compared to other manufacturing methods. Additionally, metal components have a long lifespan, which reduces the need for replacements and repairs.

In industries like automotive and construction, the push toward sustainability has led to increased use of recycled metals in fabrication processes, helping to lower environmental impacts. The durability and longevity of sheet metal parts contribute to a reduction in material consumption, waste generation, and energy usage over time

Conclusion

Modern industry relies heavily on sheet metal production, which spurs innovation in a variety of sectors. The process creates the goods we use on a daily basis, from electronics and construction to automotive and aerospace, making sure they are strong, effective, and visually pleasing. Sheet metal fabrication will continue to be at the forefront of industrial development as technology advances, allowing the production of innovative goods that satisfy the needs of a world that is constantly changing.