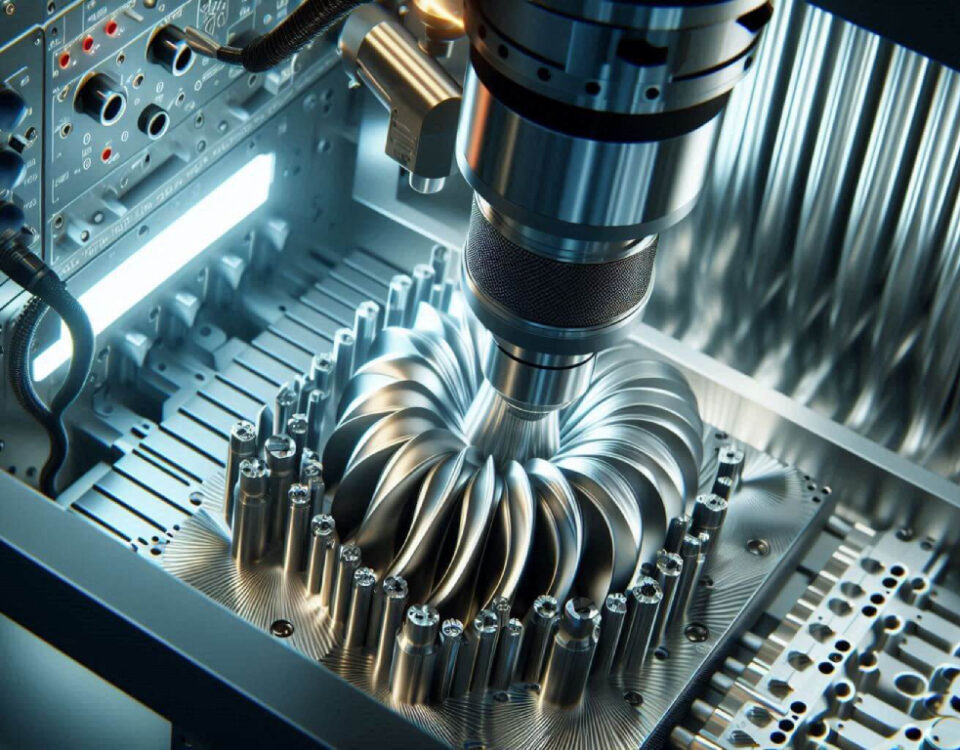

How CNC Milling Is Shaping the Aerospace Industry

21 November 2024

The Role of CAD/CAM Software in CNC Machining

29 November 2024Introduction

For a very long time, space travel has represented humanity's desire to invent and discover new things. Every advancement, from the first satellite launches to the audacious idea to settle humans on distant planets, has involved overcoming difficult obstacles. Additive manufacturing, also known as 3D printing, has become one of the most revolutionary technologies in this industry in recent years. Our method to building tools, buildings, and equipment for space missions has been completely transformed by its capacity to develop objects layer by layer utilizing digital designs.

The capacity of 3D printing to maximize resource use, lower expenses, and add a degree of flexibility not seen in conventional manufacturing techniques is what makes it particularly innovative in the context of space exploration. 3D printing's ability to bring manufacturing skills into space has created opportunities that go well beyond solving real-world issues; it is changing our perspective on what is feasible in space. 3D printing is not only improving existing capabilities but also influencing the direction of interstellar travel in the future, from creating medical instruments during trips to constructing dwellings on distant planets utilizing local materials.

What Is 3D Printing?

Fundamentally, 3D printing is a manufacturing technique that uses a digital model to guide the layer-by-layer deposition of material to produce three-dimensional objects. Additive manufacturing creates things from the ground up, as contrast to traditional subtractive manufacturing, which involves cutting or carving an object out of a larger piece of material. Reduced material waste, increased design freedom, and the capacity to create complex structures that would be unachievable with traditional methods are just a few benefits of this approach.

It is impossible to overestimate the importance of these advantages for space exploration. There are significant logistical and budgetary ramifications for every kilogram sent into space. Conventional techniques frequently lead to excessive material use, which is unfeasible in settings with little resources. On the other hand, the effectiveness of 3D printing guarantees that no material is wasted by enabling exact material use. Furthermore, the utility and performance of components—whether they be tools, spaceship parts, or even entire habitats—are improved by the ability to generate complicated designs on demand.

Because of its versatility, this technology is particularly useful in space, where mission needs might change quickly and conditions are unpredictable. For instance, the International Space Station (ISS) can lessen its dependency on resupply flights from Earth by using a 3D printer to create replacement parts or specialized tools as needed. The technology's potential uses in space will only increase as it develops, providing answers to problems that were previously thought to be intractable.

3D Printing in Space Exploration: Transformative Applications

1. Creating Spacecraft Components On-Demand

From a lack of storage capacity to the high expense of supply transportation, space missions encounter enormous logistical obstacles. By making it possible to produce necessary parts directly in space, 3D printing solves these problems. The International Space Station (ISS) now has 3D printers thanks to NASA's In-Space Manufacturing (ISM) program, which enables astronauts to create tools, replacement parts, and customized equipment as needed.

Missions can now upload digital blueprints for a particular purpose and send them to a 3D printer on the ISS, eliminating the need to bring every possible item from Earth. For example, NASA demonstrated the ability to save time, weight, and money when a wrench was needed aboard the ISS by sending an electronic design file that was manufactured in a matter of hours. Additionally, its adaptability lowers the possibility of mission delays brought on by equipment shortages.

2. Building Habitats Using Extraterrestrial Resources

There are particular difficulties when building dwellings on the Moon or Mars. Given the conditions on these celestial worlds, using typical building materials would be wasteful and their transportation is extremely expensive. With in-situ resource utilization (ISRU), which uses locally available resources to construct structures, 3D printing provides a sustainable substitute.

Lunar regolith, or moon dust, for example, can be combined with binding agents and 3D printed into solid building blocks, according to tests. Shelters that are resistant to radiation, severe temperatures, and micrometeoroid impacts can then be built using these blocks. In order to prepare the way for future colonies, businesses such as ICON are working with NASA to develop technology that will allow them to 3D print large-scale habitats. This strategy maximizes the utilization of existing resources while reducing the requirement for materials obtained from Earth.

3. Printing Food for Long-Term Space Missions

Food that has been 3D printed represents yet another advancement in space technology. Providing astronauts with a range of wholesome meals is becoming an increasingly urgent task as the number of long-term space missions rises. For multi-year missions, traditional food packing is unfeasible due to its weight and the limited shelf life of certain items. Compared to pre-packaged meals, astronauts can manufacture meals on-demand by combining raw materials in a printer using 3D printing, which offers far more flexibility and variety.

These food printers might produce meals that are suited to the nutritional requirements of astronauts using a range of substances, including powders high in protein, carbs, and lipids. Even sophisticated foods like pizzas, which businesses like BeeHex have already tested on Earth, may be produced by this technology. In addition to receiving customized meals that fit their tastes, astronauts can use 3D food printing to maximize the nutritional value of their meals for long-duration travel. In missions to Mars, where astronauts will have to survive for extended periods of time without resupply from Earth, this technology is set to play a crucial role.

4. Manufacturing Lightweight and Complex Components

One of the most important factors in space exploration is weight reduction. Because the cost of launching one kilogram into space increases significantly, it is essential to use lightweight materials and efficient manufacturing techniques. By enabling the production of intricate, lightweight components that would be challenging or impossible to do with conventional manufacturing techniques, 3D printing provides an inventive alternative.

For example, the ability of 3D printing to produce complex interior structures can be used to optimize parts for rockets, satellites, and spacecraft. As a result, overall mass is reduced without compromising performance or strength. SpaceX's use of 3D printing to create parts for its Raptor engines is a perfect illustration. SpaceX can increase the launch efficiency and lower the bulk and cost of its rockets by utilizing 3D-printed components. Additionally, as we move toward deeper space exploration, the capacity to fabricate these components in space could greatly improve mission sustainability. 3D printing offers lightweight and high-performance solutions for a variety of applications, including the production of complex satellite components and rocket parts.

5. Recycling Waste into Useful Materials

Any space mission will inevitably produce trash, and since space has few resources, controlling this waste becomes essential. By allowing astronauts to recycle waste materials like plastic packaging, outdated equipment, or useless tools and turn them into valuable raw materials for future manufacturing, 3D printing offers a potent alternative. This procedure lowers the requirement for resupply flights headquartered on Earth and drastically cuts down on waste.

For instance, the Refabricator is a device on the ISS that turns waste plastic into filament that can be 3D printed. With the use of this method, astronauts can recycle outdated plastic products and use the material to print new tools, replacement components, and other necessary items. On long-duration trips to Mars, when waste recycling would be essential to spaceship maintenance and meeting humans' needs without periodic resupplies, such systems would prove indispensable. A major factor in increasing the sustainability and economic viability of space exploration is this innovation in trash management and recycling.

6. Producing Medical Tools and Supplies

Medical crises in space are a serious worry, particularly during extended missions when there is no access to treatment on Earth. On-demand printing of medical equipment and supplies gives astronauts the ability to manage potential medical emergencies. From the spacecraft, astronauts can use 3D printing to create things like surgical instruments, diagnostic equipment, or even personalized bracing for injuries.

This feature is especially crucial in emergency scenarios where every second matters. Apart from conventional instruments, bioprinting developments have the potential to transform healthcare in space. Researchers are investigating the possibility of printing human cells, skin, or even organs for transplantation. Bioprinting is the process of printing biological tissues. This could allow astronauts to use on-site, custom-printed remedies to treat severe medical conditions including organ failure or tissue damage. The capacity to provide medical supplies on-demand could greatly enhance astronaut safety and health as space exploration expands beyond Earth's orbit.

7. Designing Custom Tools for Spacewalks

Extravehicular activities (EVAs), such as spacewalks, call for specialized equipment to do particular objectives. It is not feasible to carry a wide range of tools from Earth, but 3D printing offers a means of producing specialized equipment for certain missions.

For instance, astronauts could have to check equipment with special setups or fix a satellite. An onboard 3D printer can rapidly create a tool made specifically for the job rather than relying on makeshift tools. NASA printed a customized ratchet wrench on board the ISS to show off this capability. Because of this flexibility, astronauts are constantly prepared to tackle unforeseen difficulties during EVAs.

8. Advancing Satellite and Probe Production

Weight and size limitations frequently affect the production of satellites and space missions. Conventional satellite construction and assembly techniques necessitate extensive pre-launch packing and assembly, which raises launch complexity and costs. Building spacecraft and satellite components in orbit itself is now possible thanks to 3D printing. This makes it possible to use the restricted payload capacity during launches more effectively by eliminating the need to transfer bulky, pre-assembled equipment.

Space-printed satellites can be customized to meet unique mission requirements by being developed and built as needed. Additionally, this method provides the freedom to alter designs in midair to accommodate any last-minute mission modifications or unanticipated difficulties. In order to provide more affordable, scalable, and flexible choices for satellite production and deployment, NASA has suggested a future mission in which 3D printers might create entire satellite structures in low-Earth orbit or beyond.

9. Developing Self-Repairing Spacecraft

Spacecraft in orbit are subjected to extreme conditions, including cosmic radiation, temperature fluctuations, and high-speed micrometeoroid impacts. Any minor damage to a spacecraft’s exterior could compromise its integrity, making long-term missions especially risky. 3D printing could play a significant role in developing self-repairing spacecraft by integrating materials that automatically react to damage.

For instance, scientists are developing polymers with tiny repair fluid capsules. The capsules rupture when these materials are harmed, releasing the fluid to plug the holes or fissures. When paired with 3D printing, this self-healing ability may enable spacecraft to fix themselves while in orbit, increasing their lifespan and protecting humans. It might also offer a way to maintain equipment continuously, which would be useful in deep-space missions where there are few repair choices and it is not practical to return to Earth.

10. Facilitating Rocket Design and Manufacturing

Many costly and time-consuming procedures are involved in the typical rocket design and production process. Every part needs to be meticulously designed, put together, and tested. This procedure is being revolutionized by 3D printing, which makes it possible to create intricate rocket components like engines, combustion chambers, and rocket nozzles in a single piece. This streamlines the assembly process in addition to cutting down on production time.

The capacity to create parts with complex internal geometries that are lighter and more effective than conventional designs is one of the primary advantages of employing 3D printing in rocket manufacturing. By employing 3D printing to build whole rockets, businesses like Relativity Space are cutting down on the time and expense needed to send payloads into orbit. Engineers can test and iterate more quickly thanks to this technology's ability to quickly alter designs. Additionally, the potential for rocket production and launch straight from orbit may be made possible by the capacity to print rockets in space, opening the door to more regular and effective space travel.

The Future of 3D Printing in Space

The potential of 3D printing keeps growing in fascinating and revolutionary ways as space exploration gets more ambitious and the objective of permanent human habitation beyond Earth becomes closer. Imagine that astronauts actively manufacture everything on Mars, from their living quarters to their tools, rather than merely depending on pre-packaged materials and supplies. The days of launching bulky payloads from Earth or waiting for replenishment missions are coming to an end thanks to 3D printing. This technology has the potential to completely transform space missions by increasing their independence, economy, and flexibility.

The concept of printing dwellings directly onto foreign worlds, such as Mars or the Moon, is among the most innovative possibilities. Local resources that were previously regarded as waste, like Martian dirt or lunar regolith, may be used by astronauts to make sturdy building materials for their shelters. In addition to shielding astronauts from space's harsh elements—such as intense heat, radiation, and micrometeoroid impacts—these homes might be modified and enlarged to meet the colony's changing needs. Without having to wait for supplies to come from Earth, human settlers might continuously improve and expand their infrastructure by using 3D printing, opening the door for long-term, sustainable colonization.

With the convergence of 3D printing and artificial intelligence (AI), automated construction systems may be able to develop intricate infrastructure on far-off planets before human crews even reach them in the future of space exploration. By pre-fabricating dwellings, research stations, and even mining operations on asteroids, moons, or other celestial bodies, robots with AI and 3D printing capabilities could increase the efficiency of space exploration while lowering the hazards to human life. Pre-programmed to utilize the distinct materials present on many planets, these systems may develop structures that are most appropriate for their environments while simultaneously modifying and improving their construction methods in real time.

We can anticipate more advancements that will improve the efficiency of space travel and habitation as 3D printing technology develops. In order to lessen reliance on Earth for essential tools and hardware, this might involve producing specially designed spaceship components while in orbit. The logistical difficulties of delivering resources from Earth would be eliminated if rocket parts or even fuel could be printed in orbit or on the moon. This would greatly increase the viability of deep-space missions and even asteroid mining operations. Such advancements have a wide range of potential applications, and as technology advances, it will surely play a key role in humanity's attempts to investigate and eventually colonize space.

Conclusion

3D printing is a paradigm change that is reevaluating how we approach space travel, not just a technical advancement. Its uses are as diverse as the universe itself, ranging from facilitating environmentally friendly building on other worlds to transforming spacecraft architecture and space mission logistics. 3D printing will be essential to achieving humanity's lofty aspirations of visiting the Moon, Mars, and beyond. For long-term space missions, the technology will enable the construction of dwellings, the production of tools, the maintenance of equipment, and even the on-demand printing of biological materials.

Space exploration could become more autonomous, flexible, and sustainable with the use of 3D printing in conjunction with AI, robots, and bioprinting. Whether it's building their homes on far-off planets or developing life-saving medical treatments, it's about enabling astronauts to develop their own solutions to the problems they face, not just about printing things in space. The future of 3D printing is surely linked to the future of space travel. The technology that will enable us to push the limits of human exploration one layer at a time will be 3D printing.