Automotive

Shaping Automotive

Excellence with CNC Precision

- Turning Ideas into Automotive Reality with CNC

- Precision Machining Fuels Automotive Advancement

- Empowering Automotive Vision with CNC Excellence

Our CNC Machining Service in

Automotive Industry

Welcome to China Milling Automotive Parts Manufacturing, where excellence meets innovation in the automotive industry. With a proud legacy of delivering top-quality products and cutting-edge machining solutions, China Milling has established itself as a trusted name among automotive manufacturers and enthusiasts alike.

Set for Automotive Excellence

In the realm of OEM aerospace parts, where the pursuit of excellence requires the tightest tolerances and the most advanced precision machines, China Milling stands tall as the premier machine shop for the job. From concept to reality, we transform your aerospace visions into meticulously crafted components that soar to new heights of performance and reliability.

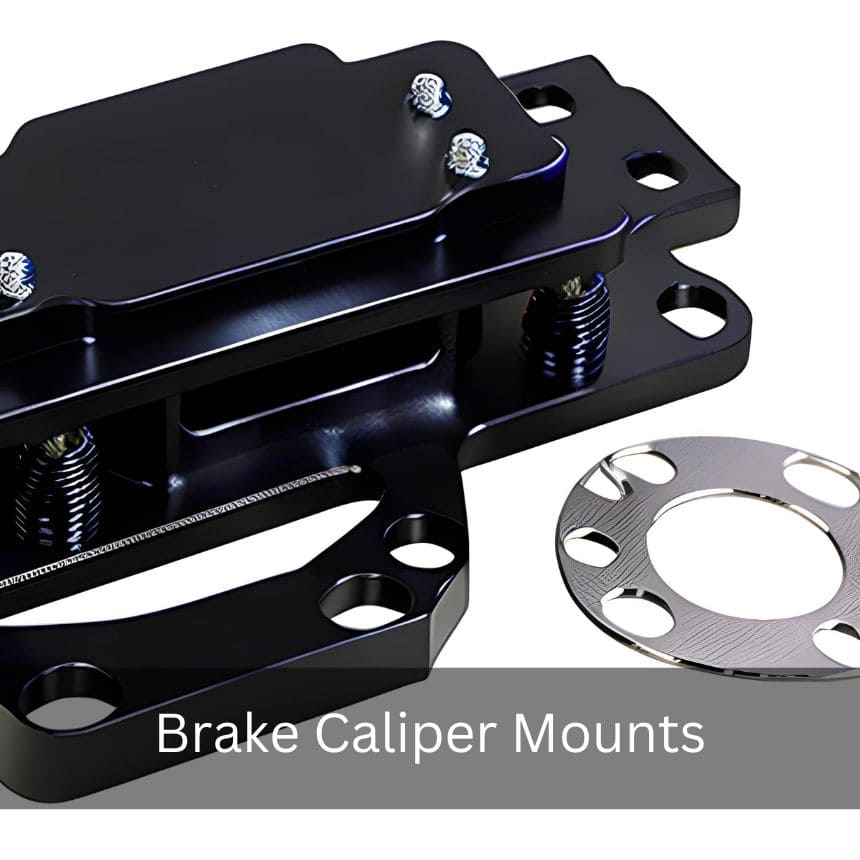

CNC machining has become a game-changer in automotive manufacturing, revolutionizing the production of critical components with unmatched precision and efficiency. Leveraging Computer Numerical Control (CNC) technology, a wide range of automotive parts can be manufactured to exacting standards, elevating performance and reliability.

Automotive Parts Made by CNC Machining:

Engine Components

Cylinder heads, pistons, and crankshafts

- Crafting Cylinder Components

- Optimized Power Combustion

- Improved Fuel Efficiency

Suspension Components

Control arms, shock absorber bodies, and steering knuckles

- Stable Handling

- Quick Response

- Enhanced Safety

Transmission Parts

Gears, shafts, and housings with tight tolerances

- Precise Gear Components

- Tight Tolerance Shafts

- Seamless Power Transfer

Interior Components

Dashboard components, door handles, and control knobs

- Elegant Interior Crafting

- Functional Aesthetics Blend

- Enhanced Driving Experience

With CNC machining at the forefront of automotive manufacturing, the industry witnesses unprecedented levels of precision and innovation, driving the creation of high-quality automotive parts that set new standards for performance, safety, and driving pleasure.

Automotive Parts

Creating automotive parts using CNC machining offers several advantages:

In other word, leveraging CNC machining to create automotive parts delivers precision, efficiency, versatility, and cost-effectiveness. It empowers automotive manufacturers to produce high-quality components that meet the rigorous demands of the industry while fostering innovation and driving progress in the automotive sector.

China Milling's impact extends far beyond its headquarters. With a robust global presence, we have successfully established strong partnerships with automotive manufacturers and suppliers across the world. Our extensive distribution network enables us to seamlessly deliver our products to customers in different regions, ensuring timely availability and reliable support.

We understand that the automotive industry is diverse and dynamic, with unique requirements varying from one market to another. Our global reach empowers us to cater to these diverse needs, adapting our solutions to suit local preferences and regulations.

At China Milling Automotive Parts Manufacturing, we believe that innovation, sustainability, and customer-centricity are the cornerstones of our success. As we march confidently into the future, we reaffirm our commitment to delivering superior automotive components and machining solutions that drive progress and shape the mobility landscape.

Our journey towards excellence is powered by our valued partnerships with clients and stakeholders across the globe. Together, we forge ahead, building a greener, more efficient, and interconnected automotive world.

As we embrace new challenges and opportunities, China Milling remains steadfast in its dedication to providing the highest-quality products, advanced technology, and exceptional customer service. Whether you are an automotive manufacturer seeking reliable components or an enthusiast looking for top-tier performance, China Milling is here to exceed your expectations.

Thank you for joining us on this exciting journey towards automotive excellence. Reach out to us today and experience the China Milling difference. Together, let's drive innovation and shape the future of mobility.

Let's Start a New Project Now!

At China Milling Automotive Parts Manufacturing, we're driven by innovation, sustainability, and customer-centricity. With global partnerships, we're shaping an interconnected, greener automotive world. Committed to excellence, we provide top-quality products, advanced tech, and stellar service. Join us in driving innovation and shaping the future of mobility.