The Art of Custom Metal Fabrication: Unlocking Endless Possibilities

10 May 2024

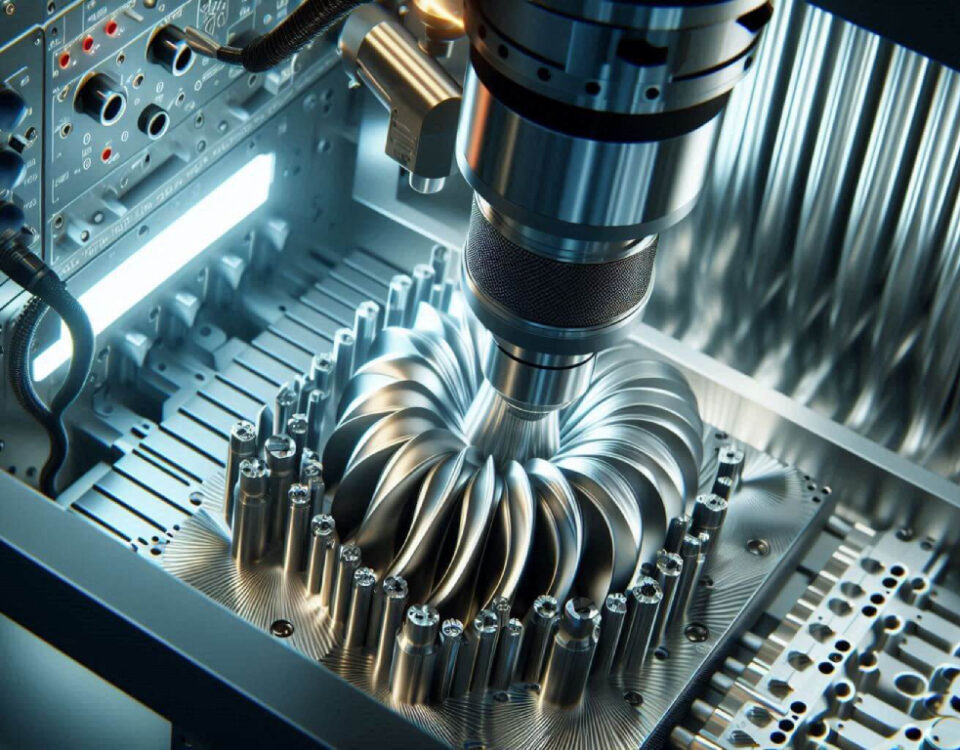

A Deep Dive into Screw Machining Techniques

17 May 20241. What are the failure modes of mechanical parts?

Mechanical parts can fail in various modes, including fracture, plastic deformation, excessive elastic deformation, excessive wear or damage of the working surface, strong vibration, loose connections, slippage of friction transmission, and more. These failures can be categorized into four types: overall fracture, excessive residual deformation, surface damage of parts, and failure caused by disrupting normal working conditions.

2. Why do threaded connections often need to be secured against loosening? What is the essence of anti-loosening? What kinds of anti-loosening measures are there?

Answer: Threaded connections can generally meet the self-locking conditions and not loosen automatically. However, under high vibration or impact load, or when there is a significant change in temperature, the connecting nut may gradually loosen. Thread loosening occurs due to the relative rotation between thread pairs. To prevent this, anti-loosening measures must be taken during the design phase. The commonly used measures include:

1. Friction anti-loosening: Keep the thread pair intact by adding spring washers or opposing double nuts.

2. Mechanical anti-loosening: Use stop parts like slotted nuts and cotter pins to ensure anti-loosening.

3. Destruction thread pair anti-loosening: Destroy and change the thread pair relationship through the impact method.

3. The purpose of tightening threaded connections is to create pre-tightening force on the bolts

This helps to improve the reliability and tightness of the connection, preventing any gaps or relative sliding between the connected parts when they are loaded. There are several methods to control the tightening force, including measuring the torque wrench or fixed torque wrench to reach the required torque or measuring the bolt elongation to control the tightening force.

4. What is the difference between elastic sliding and slipping in belt drive? When designing a V-belt drive, why should we limit the dmin of the small pulley?

Answer: Elastic sliding is a natural occurrence in belt drives and cannot be avoided. It takes place when there is a difference in tension between both sides of the band, especially when it is made of an elastomer. Overloading can cause slippage, which is a preventable form of failure. Slip occurs on the smaller pulley due to the greater tension difference that arises from external loads. This leads to an increase in the area of elastic sliding, which occurs in the wrapping angle. Elastic sliding is a quantitative change, while slipping is a qualitative change. The small diameter, small wrapping angle, and small friction contact area of the small wheel make it more susceptible to slipping.

5. Why is the allowable contact stress of gray cast iron and aluminum iron bronze turbines related to the sliding speed of the tooth surface?

Answer: Tooth surface gluing is the primary failure mode of gray die-cast iron and die casting aluminum iron bronze turbines. This type of gluing is caused by the sliding speed, which means that the allowable contact stress is also dependent on the tooth sliding speed. On the other hand, cast tin bronze turbines mainly fail due to tooth surface pitting, which occurs because of contact stress. Therefore, the allowable contact stress in cast tin bronze turbines is not associated with the sliding speed.

6. Name the common motion rules, impact characteristics and application occasions of the cam mechanism follower.

Answer: There are three laws of motion: the law of constant velocity, the law of constant acceleration and deceleration, and the law of simple harmonic motion. The law of constant velocity is used in low-speed and light-load situations and has a rigid impact. The law of constant acceleration and deceleration is used in medium and low-speed situations and has a flexible impact. The law of simple harmonic motion has a flexible impact when there is a stop interval and is used in medium and low-speed situations. However, when there is no stop interval, it has no flexible impact and is used in high-speed applications.

7. The basic laws of tooth profile meshing state that

When two tooth profiles are in contact, the common normal line passing through the contact point must intersect a specific point on the connecting center line. This ensures a constant transmission ratio between the two profiles, regardless of where they are in contact.

8. What are the methods for circumferential fixation of parts on the shaft? (Indicate four or more methods)

Circumferential fixing: key connection, spline connection, interference fit connection, set screw, pin connection, expansion connection

9. What are the main types of axial fixing methods for parts on shafts? What are the characteristics of each? (Indicate more than four types)

Axial fixation: The shaft shoulder, shaft collar, shaft sleeve, shaft end baffle, elastic retaining ring, shaft shoulder, shaft collar, and sleeve are securely fixed and capable of withstanding larger axial forces. The elastic retaining ring can withstand smaller axial forces, while the shaft end baffle is used to fix the shaft end machining 5 axis parts in place.

10. Why does a closed worm drive need to perform thermal balance calculations?

The worm drive has high friction due to relative sliding, and thermal balance calculation is necessary because poor heat dissipation of the closed worm drive can cause gluing.

11. In gear strength calculation, what are the two strength calculation theories? Which failures are targeted? If the gear transmission is a closed soft tooth surface transmission, what are its design criteria?

Answer: When designing gear transmissions, two important factors must be considered: the contact fatigue strength of the tooth surface and the bending fatigue strength of the tooth root. The former is concerned with the fatigue pitting failure of the tooth surface, while the latter focuses on the fatigue fracture of the tooth root. The gear transmission is a closed soft tooth surface transmission, which means it must be designed according to the contact fatigue strength of the tooth surface, and the bending fatigue strength of the tooth root should be checked to ensure the transmission's durability.

12. What are the functions of couplings and clutches? What's the difference between the two?

Answer: Couplings and clutches are used to connect two shafts and enable them to rotate together and transmit torque. Although both couplings and clutches serve the same purpose, there is a fundamental difference between them: the two axes connected by a coupling cannot be separated during operation. The two axes can only be separated by disassembling the parts after shutdown. On the other hand, clutches can separate or join the two axes at any time during the machine's operation.

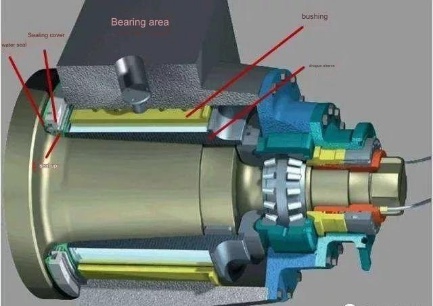

13. Explain the necessary conditions for oil film bearing.

Answer: In order for lubrication to occur, there are a few requirements:

1. A wedge-shaped gap needs to be created between the two surfaces that are moving relative to each other.

2. The two surfaces separated by the oil film should have a certain relative sliding speed, and the direction should ensure that the lubricating oil enters from the larger opening and exits from the smaller opening.

3. The lubricating oil must have a certain viscosity, and there must be enough oil supplied to ensure proper lubrication.

14. The code 7310 describes an angular contact ball bearing which has a medium diameter series with a 50mm inner diameter.

It can withstand both radial and axial loads in one direction, has a high limit speed, and is typically used in pairs.

15. In a transmission system that consists of gear transmission

belt transmission, and chain transmission, which transmission should be placed at the highest speed, and which transmission should be placed at the lowest speed? Also, why is it arranged this way?

Generally, the belt drive should be arranged at the highest level, while the chain drive should be arranged at the lowest level. This is because the belt drive has certain advantages, such as smooth transmission buffering and vibration absorption, that make it beneficial for the motor when placed at a high-speed level. On the other hand, the chain drive tends to make noise when working and is more suitable for low-speed applications. Therefore, it is typically arranged at the low-speed level in a transmission system.

16. What causes uneven chain transmission speed? What are its main influencing factors? Under what circumstances can the instantaneous transmission ratio be kept constant?

Answer: The uneven chain transmission speed is mainly caused by the polygonal effect of the chain transmission. The main factors that affect this are the chain speed, chain pitch, and the number of sprocket teeth. If the number of teeth of the large and small sprockets is equal (z1=z2) and the center distance of the transmission is exactly an integer multiple of the pitch p, then the instantaneous transmission ratio will remain constant at 1.

17. In a cylindrical gear reducer, why is the tooth width b1 of the small gear slightly larger than the tooth width b2 of the large gear? When calculating strength, the tooth width coefficient ψd is calculated according to b1 or b1? Why?

Answer: To prevent the meshing tooth width from reducing and the working load from increasing due to axial misalignment of the large and small gears caused by assembly errors, it's recommended that the small gear tooth width (b1) be slightly larger than the large gear tooth width (b2). Additionally, the tooth width coefficient (ψd) should be larger when calculating the gear tooth width (b2), as the large gear tooth width (b2) is the actual contact width when a pair of cylindrical gears mesh.

18. Why should the diameter of the small pulley d1≥dmin and the wrap angle of the driving pulley α1≥120° in the reduction belt transmission?

It is usually recommended that the belt speed is between (5~25) m/s. What will be the impact if the belt speed exceeds this range?

Answer: The diameter of the small pulley affects the bending stress of the belt. Smaller pulleys may cause excessive bending stress, so the minimum diameter of the pulley must be limited.

The wrap angle (α1) of the driving pulley affects the maximum effective tension of the belt. A smaller wrap angle means a smaller maximum effective pulling force. To prevent slipping and increase the maximum effective pulling force, the wrap angle should be at least 120°.

The belt speed affects the required effective pulling force. A low belt speed means a smaller required effective pulling force, but if it is too low, the number of belts may increase and make the belt drive structure larger. A high belt speed means that the centrifugal force may get too large, so the belt speed should be between 5 and 25 m/s.

19. Advantages and disadvantages of rolling spiral

Answer: Advantages:

1) The mechanism has minimal wear and can be adjusted to eliminate gaps and increase stiffness, resulting in high transmission accuracy.

2) It can convert linear motion into rotational motion and does not possess self-locking properties.

Disadvantages:

1) The structure of this mechanism is complex and challenging to manufacture.

2) In some cases, additional self-locking mechanisms may be required to prevent reversal.

20. What is the key selection principle?

Answer: When selecting a key for a connection, there are two important aspects to consider: type selection and size selection. Type selection should be based on the key connection's structural characteristics, usage requirements, and working conditions. On the other hand, size selection should be based on standard specifications and strength requirements.

The size of the key is determined by its cross-sectional size (key width and key height) and its length. The cross-sectional size (b*h) is selected from the standard based on the diameter (d) of the shaft. The length of the key (L) can generally be determined according to the length of the hub, which is L≦ , the hub length for guide flat keys. It depends on the length and sliding distance of the hub. In general, the hub length (L') is approximately (1.5-2)*d.

With a significant share in the global market for custom cnc machining parts and die casting aluminum parts, Anebon has strong economic strength and offers excellent sales service. The company has established a faith, friendly, and harmonious business relationship with customers in different countries, including Indonesia, Myanmar, Southeast Asian countries, European, African, and Latin American countries.