Manufacturing

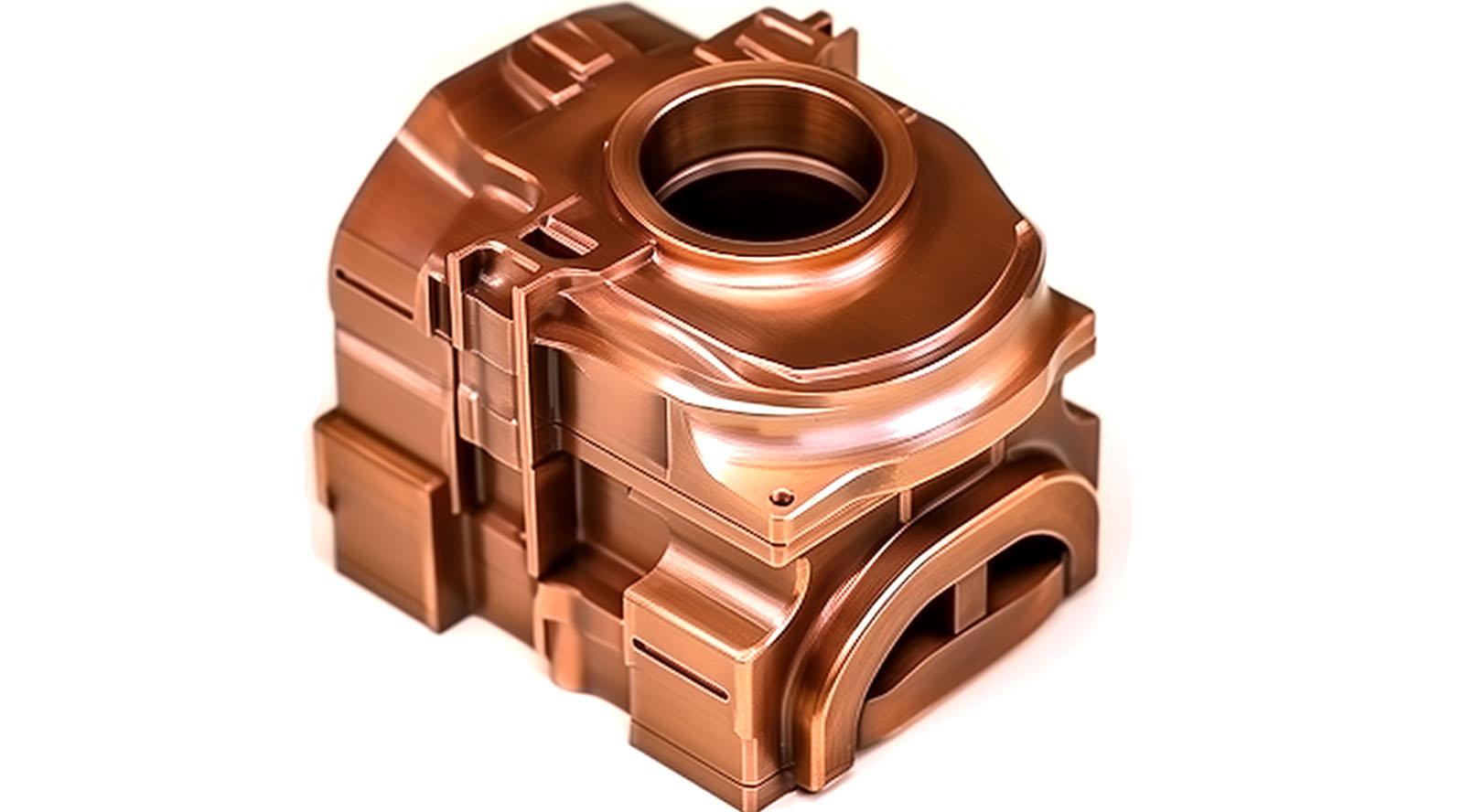

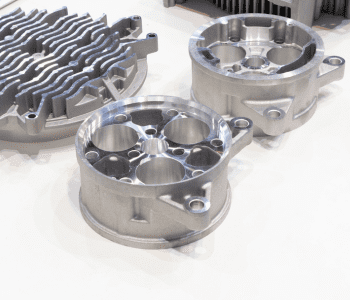

We provide Zinc die casting,

Aluminum die casting.

Low Volume, Durable Parts With

Production-Level Quality.

Our Die Casting Services

Our die casting services offer a wide range of solutions for manufacturing high quality components. Whether you need small or large batches, we can handle the job efficiently and effectively. we have become an industry-leading name, offering unrivaled precision, quality and efficiency.

Hot Chamber Die Casting

Hot chamber die casting is a manufacturing process in which molten metal, usually a zinc or magnesium alloy, is injected under high pressure into a steel mold to create complex parts. This technique offers significant advantages over traditional methods and has been widely used in the automotive, aerospace, electronics, and other industries.

Cold Chamber Die Casting

Cold Chamber Die Casting is a manufacturing process used to create complex metal parts with high precision. It involves injecting molten metal into a reusable mold, known as a die, under high pressure. Unlike its counterpart, hot chamber die casting, where the injection system remains immersed in molten metal, cold chamber die casting utilizes a separate chamber to ensure compatibility with aluminum and other metals with higher melting points.

Why choose China Milling Die Casting Parts?

Die casting is a manufacturing process that involves injecting molten metal into a mold under high pressure to produce complex metal parts. There are several kinds of raw materials commonly used in die castings, including:

Materials

|

| Aluminum |

| Aluminum is one of the most commonly used materials in die casting. It has good strength, lightweight properties and excellent corrosion resistance. In addition, aluminum has a low melting point, which is beneficial to the die casting process. |

| Commonly used Aluminum alloys: A380, A360, A390. A413, ADC-12, ADC-1 |

|

| Zinc |

| Zinc is another popular die casting material. It has excellent casting properties, good corrosion resistance, and is easy to plate or finish. Zinc is commonly used to make small, complex parts and has excellent dimensional stability. |

| Commonly used Zinc alloys: Zamak-2, Zamak-3, Zamak-5, Zamak-7, ZA-8, ZA-12, ZA-27 |

|

| Magnesium |

| Magnesium is known for its lightweight properties and high strength-to-weight ratio. It is often used in parts that require high strength and low weight, such as automotive components. |

| Commonly used Magnesium alloys: AZ91D, AM60B, AS41B |

|

| Copper |

| Copper is used in die casting for its excellent thermal and electrical conductivity. It is commonly used in electrical components, as well as heat sinks and other applications where good heat dissipation is required. |

Die castings can have a variety of surface finishes depending on the desired appearance, function and requirements of the final product. Some common die casting surface finishes include:

Die casting is a versatile manufacturing process that can be used in a wide range of industries and applications. Some common die casting applications include:

- Automotive Industry: Die casting is widely used in the automotive industry for the production of engine components, transmission housings, gearbox housings, cylinder heads and various other parts. Die castings offer high strength, dimensional accuracy, and the ability to produce complex shapes, making them ideal for automotive applications.

- Aerospace Industry: Die casting is used in the aerospace industry to produce lightweight yet strong components such as aircraft engine parts, structural components and interior fittings. Die castings have an excellent strength-to-weight ratio, high dimensional stability and excellent heat resistance.

- Electronics industry: Die casting is commonly used to produce electronic components such as computer and smartphone housings, connectors, heat sinks and electrical enclosures. Die castings have excellent electromagnetic shielding, thermal conductivity and corrosion resistance.

- Consumer Goods Industry: Die casting is used in the manufacture of a variety of consumer goods, including household appliances, power tools, sporting goods, and furniture hardware. Die casting provides the aesthetics, durability and functionality these products require.

- Medical industry: Die casting is used in the production of medical devices and equipment, such as surgical instruments, dental tools, orthopedic implants and diagnostic equipment. Die castings offer biocompatibility, corrosion resistance, and the ability to manufacture complex shapes.

- Industrial machinery: Die casting is used to produce components for industrial machinery and equipment, including pumps, valves, hydraulic components and gearboxes. Die castings offer the high strength, tight tolerances, and excellent wear resistance required for heavy-duty applications.

- Lighting industry: Die castings are often used in the manufacture of lamps, lamps and lighting accessories. Die castings allow for complex designs, excellent heat dissipation, and can be plated or painted for an aesthetic finish.

- Defense industry: Die casting is used to produce military equipment such as firearms, ammunition casings, vehicle parts and communication equipment. Die casting has the advantages of high precision, durability and light weight.

These are just a few examples of the many applications for die casting. The process is adaptable and can be used in a variety of industries requiring high-quality, cost-effective metal parts.

As an ISO9001:2015 certified company, we uphold the highest standards of quality management, ensuring that our precision-engineered parts and products contribute to a healthier and happier future for all.

Learn More >>

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Learn More >>

CNC machining has become a game-changer in automotive manufacturing, revolutionizing the production of critical components with unmatched precision and efficiency. Leveraging Computer Numerical Control (CNC) technology, a wide range of automotive parts can be manufactured to exacting standards, elevating performance and reliability.

Learn More >>

In the dynamic landscape of industrial machinery, Machining-CNC emerges as a distinctive and influential player, contributing significantly to the evolution and optimization of manufacturing processes. Anebon's journey through the realm of precision engineering and cutting-edge solutions has established it as a formidable force in the industrial machinery sector.

Learn More >>

While CNC machining is not typically used to directly fabricate electronic components like integrated circuits or microchips, it can be utilized to produce various mechanical and structural parts that are essential for electronic devices and systems.

Learn More >>

With a commitment to innovation and excellence, Machining-CNC stands as a beacon of progress, actively shaping the future of Robotics & Automation through cutting-edge solutions and CNC machining expertise.

Learn More >>