Mastering the Art: Unveiling the Secrets of Sheet Metal Stamping

23 November 2023

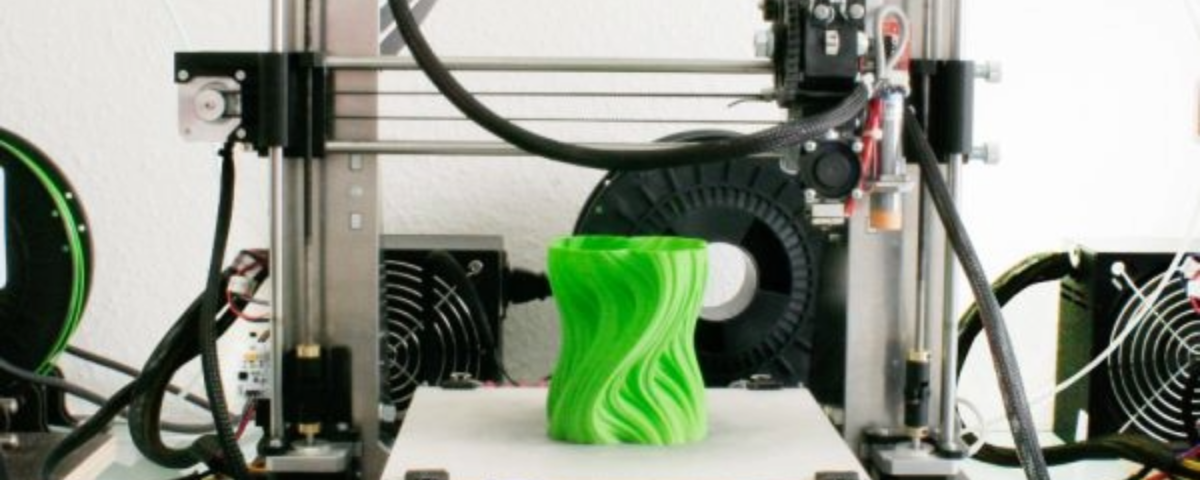

How Aluminum CNC Machining Service Is Used

29 November 2023Unlike subtractive manufacturing techniques, additive manufacturing, also known as 3D printing, is the process of joining materials to create objects from 3D model data, typically layer by layer. Today, 3D printing is being used more and more to create prototypes, proofs, and low-volume production end-use parts because it can create objects directly from digital models.

How 3D Printing Works?

3D printing, also known as additive manufacturing, works by creating a physical object layer by layer based on a digital 3D model. Here is a simplified explanation of the process:

1. Design: The first step is creating a digital 3D model of the object you want to print. This can be done using computer-aided design (CAD) software or by scanning an existing object using a 3D scanner.

2. Slicing: The 3D model is then sliced into thin layers, typically done using slicing software. Each layer is a cross-section of the final object.

3. Preparation: The 3D printer needs to be prepared by loading the appropriate material and setting up the printing parameters such as temperature, speed, and layer height.

4. Printing: The printer starts by depositing or solidifying the material layer by layer, following the sliced model. The specific method depends on the printing technology being used.

5. Layer bonding: Each layer is bonded to the previous one, typically through melting, curing, or fusing, depending on the material and technology employed.

6. Finishing: Once the printing is complete, the object may require post-processing, such as removing support structures, sanding, or applying additional treatments to achieve the desired finish.

The process can vary depending on the 3D printing technology being used, such as fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), or others. Each technology has its own specific process and materials. Overall, 3D printing enables the creation of complex and customized objects with relative ease, making it a versatile and innovative manufacturing method used in various industries, including prototyping, production, medical applications, architecture, and more.

3D Printing Service Advantages

Using a 3D printing service offers several advantages, including:

1. Cost-effectiveness: Outsourcing 3D printing to a service provider can be more cost-effective than investing in your 3D printer. You eliminate the need to purchase and maintain expensive equipment, as well as the overhead costs associated with running and operating the printer.

2. Access to Advanced Technology: 3D printing service providers often have access to state-of-the-art printers and technologies, allowing you to leverage the latest advancements without the need for upfront investment. This ensures that you can benefit from high-quality prints and take advantage of a wide range of materials and finishes.

3. Expertise and Experience: 3D printing service providers have extensive knowledge and experience in the field. They can provide valuable insights, guidance, and technical support throughout the process, ensuring optimal results. Their expertise can be particularly beneficial if you are new to 3D printing or have complex printing requirements.

4. Scalability and Flexibility: Using a 3D printing service gives you the flexibility to scale your production according to your needs. Whether you require a single prototype or a large batch of products, service providers can accommodate your requirements efficiently. This scalability allows you to respond to market demands and reduce time-to-market for new products.

5. Time-saving: Outsourcing 3D printing allows you to focus on other aspects of your business, such as design, marketing, and sales. You save time by not having to manage the printing process, troubleshooting issues, or dealing with maintenance tasks. This enables you to streamline your operations and improve overall efficiency.

6. Quality Assurance: Reputable 3D printing service providers have quality control measures in place to ensure the final product meets your expectations. They have experience in optimizing print settings, material selection, and post-processing techniques to deliver high-quality prints consistently. This reduces the risk of errors or subpar results that can occur when operating a 3D printer without sufficient expertise.

7. Wide Range of Materials and Finishes: 3D printing service providers often have access to a diverse selection of materials, including various plastics, metals, ceramics, and resins. They can also offer different finishes, such as smooth, polished, or textured surfaces, depending on your requirements. This allows you to choose the most suitable materials and finishes for your specific application.

Overall, utilizing a 3D printing service provides cost-effectiveness, access to advanced technology, expertise, scalability, time-saving benefits, quality assurance, and a wide range of materials and finishes. These advantages make it an attractive option for businesses and individuals looking to leverage the benefits of 3D printing without the need for in-house equipment and expertise.

3D Printing Service Disadvantages

While there are numerous advantages to using a 3D printing service, it's important to be aware of potential disadvantages as well. These may include:

1. Cost: While outsourcing to a 3D printing service can be cost-effective for certain projects, it may not always be the most economical option for large-scale or ongoing printing needs. Costs can add up, particularly if you require frequent or extensive printing services. It's crucial to carefully consider the cost implications and compare them with alternative options.

2. Communication and Coordination: When working with a 3D printing service, effective communication is essential to ensure that your design specifications and requirements are accurately understood. Miscommunication or a lack of clear instructions can lead to errors or subpar results. It may require additional time and effort to coordinate with the service provider, especially if you have specific or complex printing needs.

3. Limited Control: When outsourcing to a 3D printing service, you may have limited control over the printing process. This includes decisions related to printer settings, material selection, and post-processing techniques. If you have specific requirements or preferences, it's important to ensure that the service provider can accommodate them. Lack of control can sometimes lead to compromises in the outcome.

4. Turnaround Time: Depending on the workload of the 3D printing service and the complexity of your project, the turnaround time for receiving your prints may vary. If you have tight deadlines or time-sensitive projects, delays in production or delivery can be a potential drawback. It's advisable to discuss turnaround times and delivery schedules with the service provider beforehand.

5. Intellectual Property Concerns: When outsourcing your 3D printing needs, you may need to share your design files or intellectual property with the service provider. This can raise concerns about the protection of your proprietary information. It's crucial to choose a reputable and trustworthy service provider that prioritizes confidentiality and has robust security measures in place.

6. Dependency on External Services: Relying on a 3D printing service means that you are dependent on their availability and capabilities. If the service provider is unavailable or experiences issues, it can disrupt your printing plans. Having an alternative backup plan or exploring in-house printing options may be necessary to mitigate potential disruptions.

It's important to weigh these disadvantages against the advantages and consider the specific needs and circumstances of your project before deciding whether to use a 3D printing service or explore other options.

Conclusion

In conclusion, 3D printing is a groundbreaking technology that has the potential to revolutionize various industries. It works by creating three-dimensional objects layer by layer, based on a digital design. The process involves several steps, including design creation, slicing the design into layers, material selection, printing, and post-processing.

The advantages of 3D printing services are clear. They offer cost-effectiveness, access to advanced technology, expertise, scalability, time-saving benefits, quality assurance, and a wide range of materials and finishes. These advantages make it an attractive option for businesses and individuals looking to leverage the benefits of 3D printing without the need for in-house equipment and expertise.

However, it's important to be aware of potential disadvantages when using a 3D printing service. These may include cost considerations, communication challenges, limited control, turnaround time variability, intellectual property concerns, and dependency on external services. Careful evaluation of these factors is necessary to determine whether outsourcing to a 3D printing service aligns with your specific needs and goals.

Overall, 3D printing services provide an accessible and efficient way to bring designs to life, whether for prototyping, custom manufacturing, or creating personalized products. With continuous advancements in technology and increasing accessibility, 3D printing is poised to play a significant role in shaping the future of manufacturing and innovation.