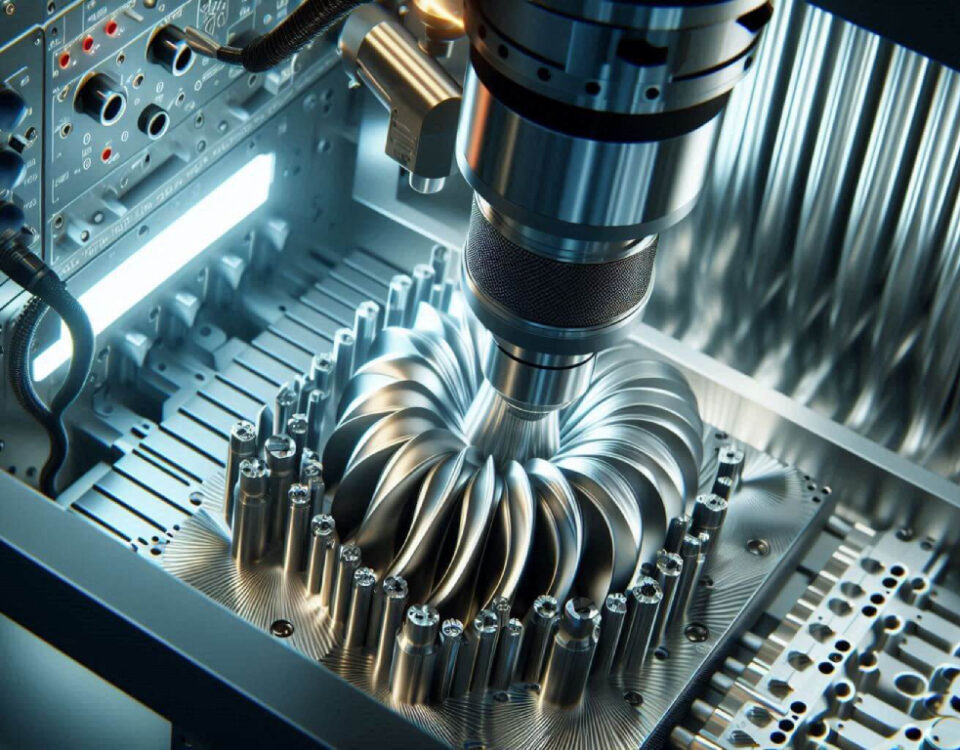

What Triggers Tool Wear and Chipping in High-Precision Machining Centers?

14 June 2024

The Ultimate Guide to Finding the Perfect Auto Spare Parts Supplier

21 June 2024For machining centers, cutting tools are consumable items that will become damaged, worn, and chipped during the machining process. These occurrences are inevitable, but there are also controllable factors, such as unscientific and irregular operation, as well as improper maintenance. By identifying the root cause, we can better address the issue.

1. Technical requirements for parts

The different technical requirements for components during processing and inspection typically include surface roughness, dimensional tolerance, geometric tolerance, heat treatment, and material surface treatment.

2. Dimensional tolerance and fit

1. Interchangeability of parts

Refers to the ability of parts or components manufactured in large quantities to be assembled into a machine without the need for selection or repair, and still meet the specified fit requirements. This means that any part can be used in place of another without any issues, ensuring smooth assembly and operation.

2. Basic concepts of dimensional tolerance

1) Definition and difference between error and tolerance

2) Basic terms of tolerance

Basic Dimension: The dimension provided by the design, such as φ50. Actual Dimension: The dimension obtained by measurement.

Limit Dimension: The two limit values for allowable dimension change based on the basic dimension.

Maximum Limit Dimension: The larger of the two limit dimensions, such as shaft φ50.007 and hole φ50.

Minimum Limit Dimension: The smaller dimension, such as shaft φ49.984 and hole φ49.982.

Dimension Deviation: There are upper and lower deviations, and dimension deviation can be positive, negative, or zero.

Upper Deviation (ES / es): The algebraic difference between the maximum limit size and the basic size is called the upper deviation, such as 50.007 - 50 = 0.007.

Lower Deviation (EI / ei): The algebraic difference between the minimum limit size and the basic size is called the lower deviation, such as 49.984 - 50 = -0.016 and 49.982 - 50 = -0.018.

Dimensional tolerance refers to the allowable variation in the size of a part. It is calculated as the difference between the maximum limit size and the minimum limit size, or the upper deviation and the lower deviation. The tolerance is always a positive number greater than zero.

For example, 50-49.984=0-(-0.016)=0.016; 50.007-49.982=0.007-(-0.018)=0.025.

Tolerance zone: The tolerance zone diagram defines an area using two straight lines that represent the upper and lower deviations. In the diagram, the upper side of the rectangle represents the upper deviation, and the lower side represents the lower deviation. The length of the rectangle has no practical meaning, and the height represents the tolerance.

Zero line: Remember the following: In the tolerance zone diagram, a reference straight line is used to determine the deviation; typically, the zero line represents the basic size. When the zero line is drawn horizontally, any deviation above the zero line is considered positive, and any deviation below the zero line is considered negative.

Tolerance Zone Diagram

3) Standard tolerance and basic deviation

The code p representing the tolerance zone consists of the basic deviation code and the tolerance grade (number), for example:

(1) Standard tolerance determines the size of the tolerance zone. There are 20 levels: IT01, IT0, IT1, ..., IT18. It is used to determine the width of the tolerance zone. See the appendix. (2) Basic deviation determines the position of the tolerance zone. It is used to determine the upper or lower deviation of the tolerance zone relative to the zero line, generally the deviation closer to the zero line. (3) Tolerance zone code and lookup table, such as: h7, D6

4) Fit

Fit: The relationship between the tolerance zones of holes and shafts with the same basic dimensions that fit each other is called fit. There are three types of fits: clearance, interference, and transition. The different tolerance zones determine the accuracy and tightness of the fit. In a clearance fit, the tolerance zone of the hole is larger than the tolerance zone of the shaft.

Interference fit (the tolerance zone of the hole is below the tolerance zone of the shaft)

Transition fit (the tolerance zones of the hole and shaft overlap)

6) Tolerance marking and reading

1) The upper and lower deviations are one size smaller than the dimension number, with the lower deviation on the same horizontal line as the dimension number.

2) When the tolerance zone is symmetrical around the basic size, meaning the upper and lower deviations are opposite numbers, we can use the marking method of "±" plus the absolute value of the deviation. For example, we can express it as φ48±0.008. In this case, the height of the deviation is the same as the height of the dimension number.

3) The upper and lower deviations must have the same number of decimal places and be aligned. When the upper or lower deviation is zero, the trailing "0" after the decimal point is generally not required.

4) In assembly drawings, only the matching code is typically marked. This code is written in fractional form, with the numerator representing the tolerance zone code of the hole and the denominator representing the tolerance zone code of the shaft.

5) When dealing with standard parts like bearings, only the tolerance zone code of the non-reference part needs to be marked. For instance, if the inner ring of the bearing matches the shaft, only the tolerance zone code of the shaft should be marked. Similarly, if the outer ring of the bearing matches the hole in the housing, only the tolerance zone code of the hole needs to be marked.

Annotations on part drawings

3. Surface roughness

1. Definition of roughness

The surface roughness of a part refers to the tiny spacing, peaks, and valleys on its processed surface. This characteristic is an important indicator for evaluating the part's surface quality and has a significant impact on its performance. Surface roughness affects the wear resistance, corrosion resistance, and overall matching quality of parts.

2. Roughness evaluation parameters:

The national standard states that roughness is assessed based on the parameter value size. Commonly used parameter values include the arithmetic mean deviation of the profile (Ra), the ten-point height of micro-roughness (Rz), and the maximum height of the profile (Ry).

The most commonly used parameter value in production is the arithmetic mean deviation (Ra) of the profile. The chart in the book provides the preferred series of Ra values recommended by the national standard.

Based on the correlation between the Ra value and commonly used processing methods, it is evident that a larger Ra value corresponds to a rougher processed surface, while a smaller Ra value corresponds to a smoother processed surface.

3. Comparison of surface roughness and finish (fourteen levels)

Surface roughness Ra value and acrylic CNC method

4. Symbols for surface roughness

5. Surface roughness marking

According to the national standard GB/T131-1993, the marking method of the surface roughness code is as follows:

1. The surface roughness number and symbol direction must comply with the figure below. The code number direction must match the dimension number direction.

2. Please take note of the following information:

Surface roughness symbols and codes are typically marked on visible contour lines, dimension limits, lead lines, or extension lines. The tip of the symbol should point from the exterior of the material to the surface. Generally, each surface on the drawing is marked with a symbol or code only once and as close to the relevant dimension line as possible. When space is limited, the symbol or code may be placed outside.

3. When all surface roughness requirements for parts are consistent, their symbols and codes should be uniformly marked in the upper right corner of the drawing. The height of these markings should be 1.4 times that of the characters in the drawing.

The most commonly used roughness symbol and code for the parts can also be uniformly marked in the upper right corner of the drawing, with the addition of the two words "other." In this case, the height of the symbol, code, and text should be 1.4 times that of the other characters in the drawing. 4. For continuous surfaces and surfaces of repeated elements (holes, grooves, teeth, etc.) on parts, the symbols and codes for surface roughness are only marked once.

4. For continuous surfaces and surfaces of repeated elements (holes, grooves, teeth, etc.) on parts, the symbols and codes for surface roughness are only marked once.

5. When CNC machining, the thread working surface profile is not depicted, the roughness code must be indicated on the lead-out line of the dimension line. The roughness of the gear tooth part can be denoted on the dividing line.

6. Center hole, keyway working surface, fillet, chamfer marking (can be simplified)

6. Shape tolerance and position tolerance

1. Concept of shape and position tolerance

In Prototype CNC milling, the acceptable range of shape and position errors is known as shape and position tolerance (often abbreviated as shape and position tolerance). Shape error refers to the variance between the actual element and the ideal geometric element, while position error refers to the variance between the actual position of multiple related geometric elements and the ideal position.

2. Basic terminology

3. Geometric tolerance items and symbols

4. Geometric tolerance code and datum code

The geometric tolerance frame consists of several small frames. The arrow of the guide line points to the surface of the measured element or its extension line. The height of the characters in the frame is the same as the height of the dimension number.

The datum code consists of the datum symbol (short, thick horizontal line), capital letters with small circles, and thin, solid lines. The letters in the datum are all written horizontally.

The code for geometric tolerance consists of a geometric tolerance symbol, frame, tolerance value, a guideline, datum code, and other related symbols.

5. Marking of geometric tolerances

Marking of measured elements

1) When measuring a contour line or surface, place the arrow of the grid guideline on the contour line or its extension line. Make sure it is clearly offset from the dimension line.

2) When measuring an axis or center plane, position the arrow of the grid guideline to coincide with the extension line of the corresponding dimension line.

6. Annotation of datum elements

1) If the datum element is a contour line or surface, the thick, short horizontal line should be positioned close to the outer contour line of the element or its extension line. It must be clearly offset from the dimension line.

2) If the datum element is an axis or center plane, the thin solid line in the datum code should be aligned with the relevant dimension line.

Anebon's pursuit and company purpose is always to "Always satisfy our consumer requirements". Anebon keeps on to acquire style and design remarkable high-quality products for each of our outdated and new customers and reach a win-win prospect for Anebon's consumers as well as us for Original Factory Profile extrusions aluminum, cnc turned part, Custom CNC machining parts. We sincerely welcome friends to barter business enterprises and start cooperation with us.

If you wanna know more or inquiry, please feel free to contact [email protected].