Services for CNC Machining

14 December 2023

Stamping Process for Sheet Metal

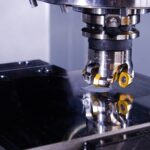

19 December 2023A CNC router, also known as a computer numerical control router, is a device used to cut intricate designs out of soft materials such as plastic, wood, expanded foam, sifted metals, and occasionally steel. Due to the cutting tool's restricted z-axis motion, a CNC router can only be used on relatively thin materials like metal plates or wooden boards. In contrast, the z-axis of motion of CNC milling machines is greater than that of this process.

A CNC machine automatically rotates a high-speed cutting tool to different coordinates in order to carve out a design using a set of computer-generated instructions known as G-code. The many parts of a CNC router, software to use with it, materials that can be cut, and some typical industrial uses for this technology will all be covered in this article.

What Is a CNC Router?

A CNC router is a computer-controlled cutting machine used for cutting various materials such as wood, plastic, foam, and aluminum. It operates based on programmed instructions to make precise cuts, engravings, or designs. CNC routers are commonly used in woodworking, prototyping, manufacturing, and other industries due to their ability to automate and accurately execute intricate cutting tasks.

How Does a CNC Router Work?

A CNC router works by interpreting digital designs or patterns and using this information to precisely cut or carve materials. The process involves the following steps:

1. Design Creation: A digital design or pattern is created using computer-aided design (CAD) software.

2. Program Input: The design is translated into instructions (G-code) that the CNC router can understand.

3. Material Setup: The material to be cut is secured to the work surface of the CNC router.

4. CNC Execution: The CNC router's computer reads the programmed instructions and guides the cutting tool (usually a rotating bit) to follow the specified paths, cutting or carving the material accordingly.

5. Completion: Once the cutting process is finished, the final product or component is ready for use or further processing.

Overall, a CNC router operates through precise computer control, allowing for accurate and repeatable manufacturing processes.

What is the Main Benefit of a CNC Router?

The main benefit of a CNC router is its ability to provide precise, automated, and repeatable cutting, carving, and shaping of various materials. This automation leads to increased efficiency, accuracy, and consistency in manufacturing processes. Additionally, CNC routers enable the creation of complex designs and patterns that would be difficult to achieve with traditional manual methods.

Which Industries Make Use of CNC Routers?

CNC routers find applications in a wide array of industries. In woodworking, they are essential for creating precise cuts and intricate designs in furniture, cabinetry, and custom woodworking projects. Sign making companies utilize CNC routers for cutting and engraving materials like acrylic, PVC, and aluminum to produce high-quality signage and lettering. Industries involved in prototyping, manufacturing, and component production rely on CNC routers to achieve accurate cuts in materials such as plastics, composites, and metals. Additionally, CNC routers are employed in foam cutting for applications in packaging, insulation, and set design across various industries. In the aerospace and automotive sectors, these routers are used for manufacturing parts, molds, and prototypes with exceptional precision and repeatability, showcasing the versatility and significance of CNC routers across a broad spectrum of industries.

What Materials Can Be Cut on a CNC Router?

CNC routers can cut a variety of materials, including:

1. Wood: CNC routers are commonly used for cutting and carving wood for furniture, cabinetry, and decorative components.

2. Plastics: Materials like acrylic, PVC, polycarbonate, and HDPE can be cut and shaped using a CNC router for applications in signage, displays, and fabrication.

3. Foam: CNC routers are employed to cut and shape foam materials for packaging, insulation, and themed environments.

4. Aluminum: Some CNC routers are capable of cutting and shaping aluminum for applications in aerospace, automotive, and general manufacturing.

5. Composite Materials: Fiberglass, carbon fiber, and other composite materials can be cut using CNC routers for manufacturing components and parts.

These are just a few examples, as CNC routers can also work with materials like MDF, particleboard, solid surface materials, and more, making them versatile tools across various industries.

Conclusion

In conclusion, a CNC router is a computer-controlled cutting machine used for precise cutting, carving, and shaping of various materials. It operates based on programmed instructions to execute intricate tasks with accuracy and repeatability. The CNC router's operation involves the interpretation of digital designs, conversion into toolpath instructions, and precise movement of the cutting tool along specified axes. This level of automation and precision makes CNC routers indispensable across industries such as woodworking, manufacturing, signage, and prototyping, where consistent, high-quality production is essential.