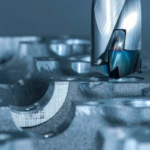

How Do You Evaluate Cutting Speed?

17 January 2024

Why Choose CNC Precision Plastic Machining of Units Over 3D Printing?

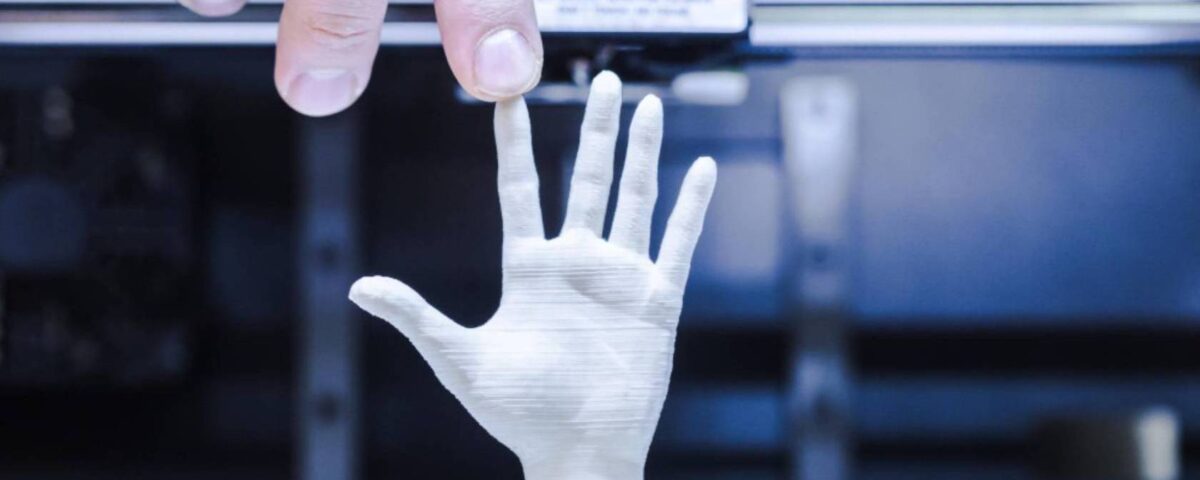

18 January 2024In the realm of modern manufacturing and design, 3D printing services have emerged as a revolutionary force, transforming the way we conceive, prototype, and produce various objects. Also known as additive manufacturing, 3D printing has evolved from a niche technology to a mainstream solution that caters to a wide range of industries. This article explores the profound impact of 3D printing services, delving into their origins, applications across diverse sectors, and the potential they hold for shaping the future of manufacturing

The Genesis of 3D Printing Services

The roots of 3D printing can be traced back to the 1980s when Charles Hull invented stereolithography, the first 3D printing technology. This groundbreaking innovation paved the way for the development of additive manufacturing processes that construct objects layer by layer from digital models. Initially used primarily for prototyping, 3D printing has undergone remarkable advancements, enabling its widespread adoption in various industries.

Applications of 3D Printing Services

- Prototyping and Product Development

One of the earliest and most prominent applications of 3D printing services is in the field of prototyping. Traditional prototyping methods often involved time-consuming and expensive processes, making it challenging for designers and engineers to iterate quickly. With 3D printing, creating physical prototypes has become significantly more accessible and cost-effective. This has led to accelerated product development cycles, allowing companies to bring innovative ideas to market faster.

- Customization in Manufacturing

The ability to produce intricate designs with 3D printing has opened new avenues for customization in manufacturing. From personalized consumer products to specialized industrial components, 3D printing allows for the creation of unique, one-of-a-kind items. This level of customization not only enhances consumer experiences but also empowers businesses to meet specific requirements with unparalleled precision.

- Medical Applications

The medical field has witnessed a transformative impact from 3D printing services. Customized implants, prosthetics, and even organs can now be produced using this technology. Patient-specific models aid surgeons in planning complex procedures, contributing to better outcomes and reduced surgery times. 3D bioprinting is an emerging frontier that holds the promise of revolutionizing organ transplantation and tissue engineering.

- Automotive Industry

Automakers have embraced 3D printing services for prototyping, creating lightweight components, and even producing end-use parts. The technology allows for the optimization of designs, resulting in vehicles that are not only more fuel-efficient but also safer. The automotive industry's adoption of 3D printing highlights its potential for enhancing efficiency and sustainability in manufacturing processes.

- Aerospace and Defense

In the aerospace and defense sectors, precision and reliability are paramount. 3D printing services enable the production of complex geometries and lightweight structures that traditional manufacturing methods struggle to achieve. This has implications for aircraft design, leading to the development of more fuel-efficient and aerodynamic structures. Additionally, the rapid prototyping capabilities of 3D printing prove invaluable in the development and testing of new aerospace technologies.

Challenges and Innovations in 3D Printing

While 3D printing services offer a myriad of benefits, there are challenges that the industry continues to address. These include material limitations, production speed, and the scalability of 3D printing for mass production. Ongoing research and development efforts are focused on overcoming these challenges, with innovations such as advanced materials, faster printing technologies, and hybrid manufacturing processes showing promise.

- Materials Advancements

The range of materials available for 3D printing has expanded significantly. Initially limited to plastics, the technology now accommodates metals, ceramics, and even composite materials. This diversification of materials enhances the applicability of 3D printing across various industries, from aerospace to healthcare. Researchers are actively exploring novel materials with improved properties, such as increased strength, flexibility, and biocompatibility.

- Speed and Scalability

Historically, 3D printing was criticized for being a slow manufacturing process, hindering its suitability for large-scale production. However, advancements in printing technologies, including faster printing methods and improved layering techniques, are addressing these concerns. Hybrid manufacturing approaches that combine traditional and additive methods are also being explored to optimize production speed without compromising on the benefits of 3D printing.

- Sustainability in 3D Printing

As sustainability becomes a focal point in manufacturing, 3D printing presents itself as a more eco-friendly alternative. The additive nature of the process generates less waste compared to subtractive manufacturing methods. Additionally, the ability to produce lightweight structures contributes to fuel efficiency in transportation and reduces the overall environmental impact of manufactured goods.

Economic Impacts and Market Trends

The economic landscape is witnessing a transformation driven by the widespread adoption of 3D printing services. As the technology becomes more accessible, businesses of all sizes are integrating 3D printing into their operations. The market for 3D printing services is experiencing steady growth, with projections indicating further expansion in the coming years.

- Market Growth and Revenue Projections

The global 3D printing market has witnessed substantial growth, fueled by increased awareness, technological advancements, and a growing demand for customized products. According to market research reports, the 3D printing market is expected to reach significant revenue milestones in the foreseeable future, driven by expanding applications across diverse industries.

- Accessibility and Affordability

Advancements in desktop 3D printers have made the technology more accessible to small businesses, educational institutions, and individual enthusiasts. Affordable 3D printing solutions enable entrepreneurs and startups to prototype and manufacture products without the need for extensive capital investment. This democratization of manufacturing has the potential to spur innovation and disrupt traditional supply chains.

- Collaborative Ecosystems and Open Source Initiatives

The 3D printing community thrives on collaboration and knowledge sharing. Open source initiatives have played a crucial role in the development of 3D printing technologies, fostering a culture of innovation and inclusivity. Online platforms and communities provide a space for designers, engineers, and enthusiasts to exchange ideas, share designs, and contribute to the continuous evolution of 3D printing.

Future Prospects and Emerging Technologies

As 3D printing services continue to evolve, the future holds exciting possibilities for the technology. Emerging trends and technologies are poised to further enhance the capabilities of 3D printing, influencing industries and shaping the way we approach design and manufacturing.

- 4D Printing

Building on the principles of 3D printing, 4D printing introduces the dimension of time. This emerging technology involves the use of materials that can respond to external stimuli, such as heat or moisture, to transform over time. 4D printing has potential applications in self-assembling structures, responsive materials, and dynamic systems, opening new avenues for innovation in fields like construction, robotics, and healthcare.

- AI and Generative Design

Artificial intelligence (AI) is increasingly being integrated into the 3D printing process through generative design. AI algorithms analyze design requirements and constraints to generate optimized and efficient structures. This synergy between AI and 3D printing enables the creation of designs that human designers might not conceive, pushing the boundaries of what is achievable in terms of complexity and performance.

- Space Exploration and Colonization

3D printing is playing a pivotal role in space exploration and colonization efforts. The ability to manufacture tools, components, and even habitats on-demand using locally sourced materials is crucial for long-duration space missions and establishing human presence on other celestial bodies. Organizations like NASA are actively exploring the potential of 3D printing in space, with experiments conducted aboard the International Space Station.

Conclusion

The evolution of 3D printing services from a niche technology to a transformative force across diverse industries reflects its profound impact on modern manufacturing and design. From rapid prototyping to customized production and innovative applications in healthcare, aerospace, and beyond, 3D printing has reshaped the way we approach the creation of physical objects.

As the technology continues to advance, addressing challenges and embracing innovations, the economic landscape is being reshaped. The accessibility of 3D printing services, coupled with collaborative ecosystems and open-source initiatives, is democratizing manufacturing and fostering a culture of innovation.

Looking ahead, emerging technologies like 4D printing, AI-driven generative design, and applications in space exploration promise to further expand the horizons of 3D printing. The journey from prototyping to mass production, from customization to sustainability, showcases the versatility and potential of 3D printing services in shaping the future of how we design, create, and build.