Unlocking the Power of Precision Machinery: Maximizing Efficiency and Accuracy in Manufacturing

3 May 2024

Detailed explanation of seven thread processing methods that cannot be missed

8 May 2024Stainless steel parts are a fundamental component in various industries, renowned for their exceptional durability and corrosion resistance. Whether you're looking for machining, fabrication, or manufacturing solutions, this comprehensive guide has got all the information you need to make informed decisions. In this article, we'll delve into the world of stainless steel parts, exploring their properties, applications, and benefits.

Our brand voice is that of a trusted industry expert, providing valuable insights to empower our readers. With over 12 years of experience, we understand the importance of delivering accurate and up-to-date information that drives results.

From understanding the different grades and types of stainless steel to exploring the diverse range of applications across industries like automotive, aerospace, and construction, this guide aims to equip you with the knowledge to optimize your project's performance and longevity.

Whether you're a beginner seeking basic knowledge or a seasoned professional looking to stay on top of the latest industry trends, this ultimate guide is your go-to resource for all things stainless steel parts. Let's dive in and unlock the potential of this remarkable material.

Properties and Characteristics of Stainless Steel

Stainless steel is a versatile material that exhibits several unique properties and characteristics. Firstly, it is highly resistant to corrosion, making it an excellent choice for applications in challenging environments. This corrosion resistance is due to the presence of chromium, which forms a thin, protective layer on the surface of the steel, preventing oxidation. Additionally, stainless steel is known for its high strength-to-weight ratio, making it suitable for applications that require both durability and lightweight components.

Another notable property of stainless steel is its heat resistance. It can withstand high temperatures without losing its strength or structural integrity, making it ideal for applications where exposure to heat is a concern. Furthermore, stainless steel is non-magnetic, which is advantageous in certain industries, such as medical and electronics, where magnetic interference can cause issues.

Types of Stainless Steel Alloys

There are numerous types of stainless steel alloys available, each with its own unique composition and properties. The most commonly used stainless steel alloys include austenitic, ferritic, and martensitic stainless steels.

Austenitic stainless steel is the most widely used type, known for its excellent corrosion resistance and formability. It contains high levels of chromium and nickel, providing superior strength and resistance to oxidation. This type of stainless steel is often used in applications such as food processing equipment, chemical processing plants, and architectural structures.

Ferritic stainless steel, on the other hand, is characterized by its magnetic properties and high resistance to corrosion, especially in acidic environments. It contains higher levels of chromium but lower levels of nickel compared to austenitic stainless steel. Ferritic stainless steel is commonly used in automotive components, exhaust systems, and kitchen appliances.

Martensitic stainless steel is known for its high strength and hardness. It can be heat-treated to achieve even greater strength, making it suitable for applications that require resistance to wear and abrasion. Martensitic stainless steel is often used in cutlery, surgical instruments, and turbine blades.

Common Applications of Stainless Steel Parts

Stainless steel parts find applications in a wide range of industries due to their exceptional properties. In the automotive industry, stainless steel is used for exhaust systems, mufflers, and various engine components. Its corrosion resistance and heat resistance make it an excellent choice for these demanding applications. Additionally, stainless steel is used in the construction industry for structural elements, handrails, and cladding due to its durability and aesthetic appeal.

The aerospace industry also relies heavily on stainless steel parts for their aircraft components. From landing gear and engine components to fuselage structures, stainless steel's strength, and corrosion resistance ensure the safety and longevity of the aircraft. Moreover, stainless steel is widely used in the food and beverage industry, where hygiene and corrosion resistance are crucial. Equipment such as tanks, pipes, and food processing machinery are often made from stainless steel to ensure the quality and safety of the products.

Advantages of Using Stainless Steel Parts

There are several advantages to using stainless steel parts in various applications. Firstly, stainless steel's corrosion resistance significantly extends the lifespan of components, reducing maintenance costs and downtime. This resistance to corrosion also makes stainless steel parts suitable for applications where exposure to harsh chemicals or environmental conditions is common.

In addition, stainless steel parts offer excellent heat resistance, making them ideal for applications that involve high temperatures or thermal cycling. This heat resistance ensures that the components maintain their structural integrity and functionality even under extreme conditions. Moreover, stainless steel is highly durable, with excellent strength and impact resistance, making it suitable for heavy-duty applications.

Another advantage of stainless steel parts is their aesthetic appeal. The material has a sleek and modern appearance, which makes it a popular choice in architectural and design applications. Stainless steel's clean and polished surface is also easy to clean and maintain, making it suitable for applications where hygiene is essential, such as in the food and medical industries.

Manufacturing Processes for Stainless Steel Parts

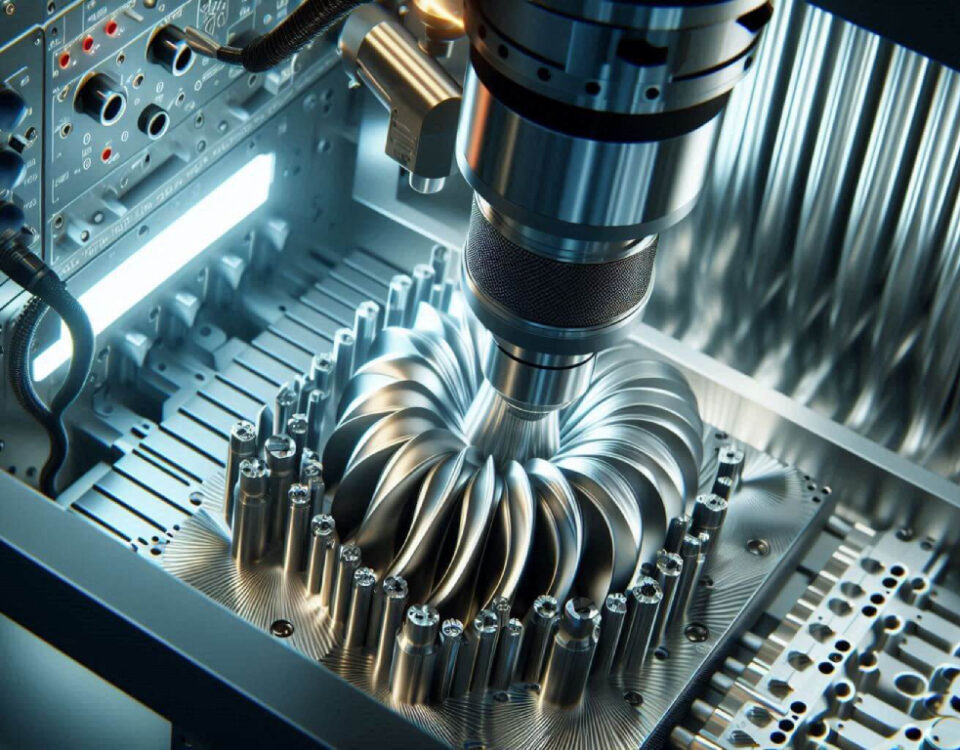

Stainless steel parts can be manufactured using various processes, depending on the desired shape, size, and complexity of the component. One of the most common manufacturing processes is machining, which involves removing material from a stainless steel workpiece using cutting tools. Machining processes such as turning, milling, and drilling allow for precise and accurate shaping of stainless steel parts.

Another manufacturing process used for stainless steel parts is fabrication. This involves cutting, bending, and welding stainless steel sheets or plates to create a desired shape or structure. Fabrication processes like laser cutting, plasma cutting, and sheet metal bending offer flexibility and customization options for stainless steel parts.

For more complex and intricate stainless steel parts, manufacturing processes like casting and forging may be utilized. Casting involves pouring molten stainless steel into a mold and allowing it to solidify, while forging involves shaping the stainless steel by applying heat and pressure. These processes are commonly used in the production of stainless steel components for the aerospace and automotive industries.

Choosing the Right Grade of Stainless Steel for Your Project

When selecting stainless steel for your project, it's essential to choose the right grade that best suits your specific requirements. The grade of stainless steel refers to its composition and properties, which can vary significantly depending on the intended application.

The most commonly used stainless steel grades include 304, 316, and 430. Grade 304 stainless steel is the most versatile and widely used, offering excellent corrosion resistance, formability, and weldability. It is suitable for a wide range of applications, including food processing equipment, architectural structures, and kitchen appliances.

Grade 316 stainless steel is known for its superior corrosion resistance, particularly in chloride environments. It is often used in marine applications, chemical processing plants, and medical equipment. Grade 316L, a low-carbon variation of 316, is commonly used in applications that require welding to maintain corrosion resistance.

Grade 430 stainless steel is a ferritic stainless steel that offers good corrosion resistance and high heat resistance. It is often used in automotive trim, kitchen appliances, and decorative applications. However, it is not as corrosion-resistant as austenitic stainless steels and may be prone to surface rust in certain environments.

Maintenance and Care for Stainless Steel Parts

To ensure the longevity and performance of stainless steel parts, proper maintenance and care are essential. Stainless steel is relatively low maintenance, but regular cleaning is required to prevent the buildup of dirt, grime, and contaminants.

To clean stainless steel parts, a mild detergent or soap can be used with warm water. Avoid using abrasive cleaners or scouring pads, as they can scratch the surface of the stainless steel. After cleaning, thoroughly rinse the parts with clean water and dry them with a soft cloth to prevent water spots or streaks.

In applications where stainless steel parts are exposed to harsh chemicals or corrosive substances, it is important to regularly inspect and clean the parts to remove any residue or buildup. Additionally, applying a protective coating or passivating the stainless steel surface can further enhance its corrosion resistance and longevity.

Cost Considerations for Stainless Steel Parts

The cost of stainless steel parts can vary depending on several factors, including the grade of stainless steel, the complexity of the component, and the quantity required. Generally, stainless steel parts tend to be more expensive than other materials due to the higher cost of raw materials and the specialized manufacturing processes involved.

However, it is important to consider the long-term cost savings that stainless steel parts offer. Due to their exceptional durability and corrosion resistance, stainless steel parts have a longer lifespan compared to other materials. This reduces maintenance and replacement costs over time, making stainless steel a cost-effective choice in the long run.

When considering the cost of stainless steel parts, it is also essential to factor in the quality and reliability they offer. Stainless steel parts are known for their superior performance and reliability, making them a worthwhile investment for critical applications where failure or downtime can have significant consequences.

Conclusion: Why Stainless Steel Parts Are a Reliable Choice

In conclusion, stainless steel parts offer exceptional durability, corrosion resistance, and heat resistance, making them a reliable choice for various industries. Whether you're in the automotive, aerospace, construction, or food and beverage industry, stainless steel parts can enhance the performance and longevity of your projects.

Understanding the properties, types, and applications of stainless steel alloys is crucial in selecting the right material for your project. Additionally, considering factors such as manufacturing processes, maintenance, and cost can help optimize the performance and cost-effectiveness of stainless steel parts.

By choosing stainless steel parts, you can ensure that your components withstand harsh environments, resist corrosion, and deliver reliable performance. With its versatility, strength, and aesthetic appeal, stainless steel is a material that continues to be at the forefront of modern engineering and manufacturing. Embrace the potential of stainless steel parts and unlock new possibilities for your projects.