Guide to Metal Fabrication: Exploring the World of Sheet Metal

11 June 2024

What Triggers Tool Wear and Chipping in High-Precision Machining Centers?

14 June 2024Enhance your production capabilities with China Precision Machining Parts from us. Our high-quality CNC machining parts are crafted with precision and delivered with efficiency. Elevate your projects today—contact us for a quote and experience the excellence of our on-demand CNC machining services. Contact us Now!

The Power of China Precision Machining Parts

Are you in need of precision machining parts that are both high-quality and cost-effective? Look no further than China. With its vast manufacturing capabilities and skilled workforce, China has emerged as a powerhouse in the precision machining industry. In fact, many businesses around the world are turning to China to produce their critical components.

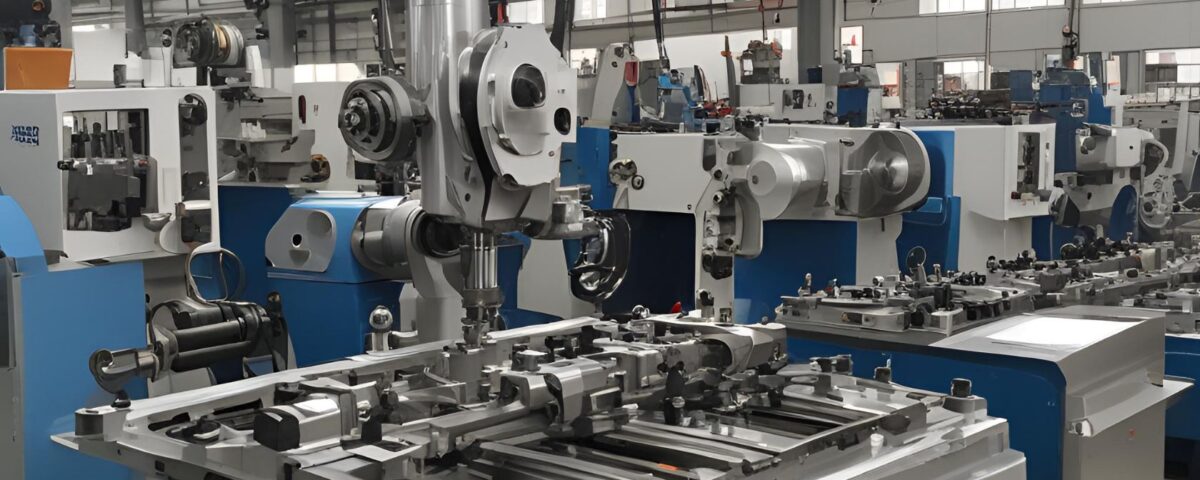

China's precision machining industry offers a wide range of services, including CNC milling, turning, grinding, and drilling. Whether you need complex parts with intricate designs or simple components, Chinese manufacturers can meet your exact specifications. Not only that, but they can deliver large quantities of parts within tight deadlines.

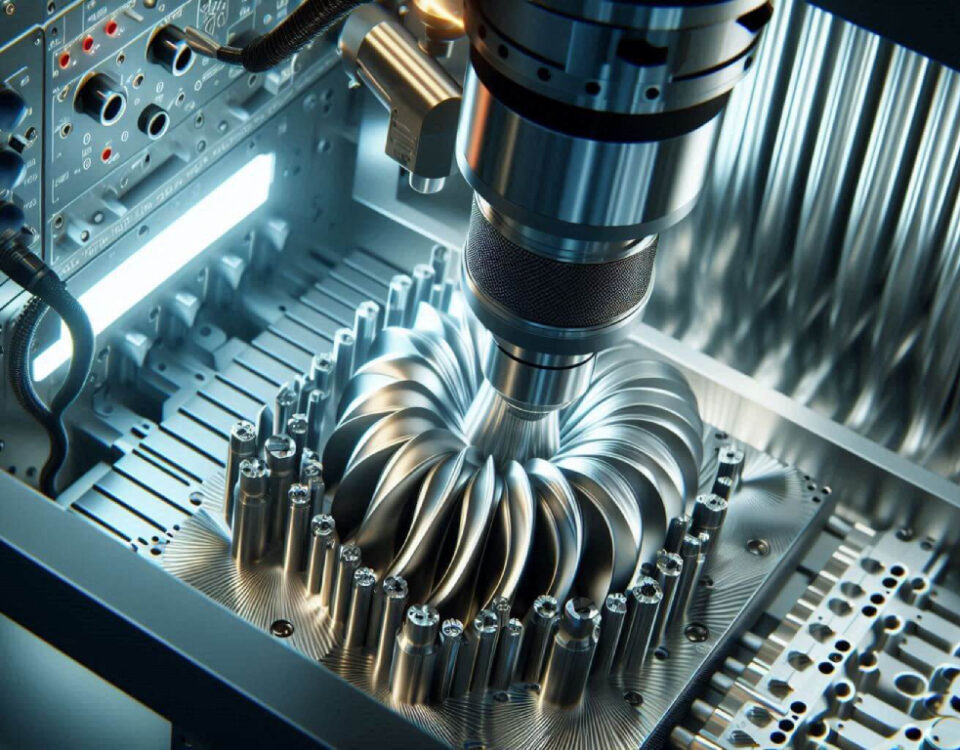

But it's not just about the quantity; it's about the quality too. Chinese manufacturers prioritize the use of advanced machining techniques and state-of-the-art equipment to ensure precision and consistency in their production. From automotive and aerospace to medical and electronics industries, China can cater to diverse sectors, delivering parts that meet the highest standards.

When it comes to precision machining parts, China stands out as a reliable and cost-effective option. So, why look elsewhere? Unleash the power of China in precision machining parts and take your business to new heights.

The Importance of Precision Machining in Various Industries

Precision machining plays a critical role in various industries, ensuring the production of high-quality components that meet stringent specifications. From aerospace to medical devices, precision machining parts are essential for the functioning of complex machinery and equipment. The accuracy and consistency provided by precision machining processes are vital in ensuring the reliability and performance of the final products. In industries where precision is paramount, such as automotive and electronics, the quality of machining parts can directly impact product functionality and safety.

The demand for precision machining parts continues to grow as industries evolve and require more sophisticated components. With the rise of advanced technologies and the need for miniaturization, the precision machining industry has become increasingly important in meeting the demands of modern manufacturing. As businesses strive for efficiency and product excellence, the role of precision machining in delivering precise and reliable parts cannot be overstated.

By harnessing the capabilities of precision machining, businesses can achieve greater levels of precision, consistency, and quality in their products. Whether it's producing intricate components for medical devices or high-performance parts for aerospace applications, precision machining is indispensable in driving innovation and progress across industries.

Overview of the Precision Machining Industry in China

China has emerged as a global leader in the precision machining industry, offering a wide range of services and solutions to businesses worldwide. With its vast manufacturing infrastructure and skilled workforce, China has positioned itself as a powerhouse in producing precision machining parts at scale. The country's expertise in CNC milling, turning, grinding, and drilling allows for the production of complex components with high precision and efficiency.

Chinese manufacturers leverage advanced machining techniques and cutting-edge equipment to deliver parts that meet the most demanding specifications. The precision machining industry in China is characterized by its ability to handle diverse requirements across industries, from automotive and aerospace to electronics and medical devices. By investing in technology and training, Chinese machining companies have elevated their capabilities to cater to a broad range of customer needs.

In addition to its technical prowess, China offers competitive advantages in terms of cost-effectiveness and production efficiency. Businesses looking to source precision machining parts can benefit from the economies of scale and streamlined processes that Chinese manufacturers provide. With a focus on quality and reliability, China has become a go-to destination for companies seeking high-quality precision components at competitive prices.

Advantages of Sourcing Precision Machining Parts from China

There are several advantages to sourcing precision machining parts from China, making it an attractive option for businesses looking to optimize their supply chain and manufacturing processes. One of the key benefits is the cost-effectiveness of working with Chinese manufacturers, who can offer competitive pricing without compromising on quality. By leveraging the lower labor and production costs in China, businesses can achieve significant cost savings while maintaining high standards of precision and quality.

Another advantage of sourcing precision machining parts from China is the availability of a wide range of services and capabilities. Chinese manufacturers are equipped to handle various machining processes, from CNC milling to Swiss turning, allowing for the production of diverse components with different specifications. This versatility enables businesses to consolidate their machining needs and work with a single provider for multiple parts, streamlining their sourcing and production processes.

Furthermore, Chinese manufacturers are known for their ability to scale production quickly and efficiently, making them ideal partners for businesses with fluctuating demand or tight deadlines. Whether it's producing small batches of custom parts or large volumes of standardized components, Chinese machining companies can adapt to the needs of their customers and deliver parts on time and within budget. The flexibility and responsiveness of Chinese manufacturers make them valuable allies in today's fast-paced and dynamic manufacturing environment.

Challenges and Considerations When Dealing with China in Precision Machining

While there are many benefits to sourcing precision machining parts from China, businesses should be aware of the challenges and considerations that come with dealing with overseas suppliers. One of the key challenges is communication, as language barriers and cultural differences can sometimes lead to misunderstandings and delays in the production process. It's essential for businesses to establish clear communication channels and expectations with their Chinese suppliers to ensure smooth collaboration.

Quality control and consistency are also important considerations when working with Chinese manufacturers in precision machining. While China boasts advanced machining capabilities, maintaining high quality standards across production batches can be a challenge. Businesses need to implement robust quality control processes and inspections to ensure that the parts they receive meet their specifications and performance requirements. Building strong relationships with suppliers and conducting regular audits can help mitigate quality risks and ensure product reliability.

Another consideration when dealing with China in precision machining is intellectual property protection. Businesses must take steps to safeguard their designs and proprietary information when sharing them with Chinese suppliers. Implementing confidentiality agreements and working with reputable manufacturers with a track record of respecting intellectual property rights can help protect businesses from unauthorized use or replication of their designs. By addressing these challenges proactively, businesses can maximize the benefits of sourcing precision machining parts from China while minimizing potential risks.

Tips for Finding Reliable Precision Machining Suppliers in China

Finding reliable precision machining suppliers in China requires careful research and due diligence to ensure that businesses partner with reputable and trustworthy manufacturers. One of the first steps is to conduct thorough background checks on potential suppliers, including verifying their credentials, certifications, and industry reputation. Working with established manufacturers with a history of delivering quality parts can provide businesses with confidence in their sourcing decisions.

It's also essential to visit the facilities of prospective suppliers in China to assess their production capabilities, quality control processes, and overall working conditions. By conducting on-site visits and inspections, businesses can gain firsthand insights into the supplier's operations and evaluate their suitability as a manufacturing partner. Building personal relationships with suppliers and establishing open communication channels can foster transparency and collaboration in the partnership.

Additionally, businesses should seek feedback and references from other clients who have worked with the prospective suppliers to gauge their performance and reliability. Testimonials and case studies can offer valuable insights into the supplier's track record and ability to meet customer expectations. By leveraging the experiences of other businesses, companies can make informed decisions when selecting precision machining suppliers in China and ensure a successful partnership.

Quality Control and Inspection Processes in China's Precision Machining Industry

Quality control and inspection processes are paramount in China's precision machining industry to ensure the consistent production of high-quality parts that meet customer specifications. Chinese manufacturers adhere to rigorous quality standards and implement comprehensive inspection protocols throughout the manufacturing process to detect any deviations or defects. From raw material inspection to final product testing, quality control procedures are integrated at every stage to maintain product integrity and performance.

Chinese machining companies utilize a variety of inspection tools and techniques, such as coordinate measuring machines (CMMs), optical comparators, and surface testers, to verify the accuracy and precision of machined components. By conducting dimensional checks, surface finish analyses, and functional tests, manufacturers can identify any discrepancies or issues early in the production process and take corrective actions to ensure product quality. Continuous monitoring and feedback mechanisms help Chinese suppliers uphold high quality standards and meet customer expectations.

In addition to in-process inspections, Chinese manufacturers also invest in employee training and quality management systems to instill a culture of quality and continuous improvement within their organizations. By empowering their workforce with the skills and knowledge to uphold quality standards, machining companies in China can enhance their production capabilities and deliver superior parts to customers. The emphasis on quality control and inspection processes underscores China's commitment to excellence and customer satisfaction in precision machining.

Cost-Effectiveness and Competitive Pricing in China's Precision Machining Market

China's precision machining market is known for its cost-effectiveness and competitive pricing, making it an attractive destination for businesses looking to optimize their manufacturing costs without compromising on quality. Chinese manufacturers benefit from economies of scale, efficient production processes, and lower labor costs, allowing them to offer competitive pricing for precision machining parts. By leveraging these cost advantages, businesses can reduce their production expenses and improve their profit margins.

Moreover, the competitive pricing in China's precision machining market does not come at the expense of quality. Chinese manufacturers invest in advanced technologies, skilled labor, and quality control measures to ensure that the parts they produce meet the highest standards of precision and performance. By striking a balance between cost-effectiveness and quality, Chinese machining companies deliver value to their customers and help businesses achieve their production goals within budget.

Businesses sourcing precision machining parts from China can benefit from the cost savings and efficiency gains that Chinese manufacturers offer. Whether it's producing prototypes, custom components, or mass-produced parts, China provides a cost-effective solution for businesses of all sizes. By capitalizing on the competitive pricing and quality assurance practices in China's precision machining market, businesses can enhance their competitiveness and drive growth in their respective industries.

Case Studies: Success Stories of Businesses Leveraging China's Precision Machining Capabilities

Several businesses have successfully leveraged China's precision machining capabilities to achieve their production goals and gain a competitive edge in the market. One such success story is a leading aerospace company that partnered with a Chinese manufacturer to produce complex components for aircraft engines. By working closely with the Chinese supplier to optimize the machining processes and quality control measures, the aerospace company was able to meet tight deadlines and stringent specifications, ultimately enhancing the performance and reliability of its products.

Another example is a medical device manufacturer that collaborated with a Chinese machining company to develop precision components for surgical instruments. The Chinese supplier's expertise in CNC milling and quality assurance processes enabled the medical device manufacturer to produce high-precision parts that met regulatory requirements and exceeded customer expectations. By tapping into China's advanced machining capabilities, the medical device company was able to enhance the effectiveness and safety of its products, driving innovation in the healthcare industry.

These case studies highlight the diverse applications and benefits of partnering with Chinese manufacturers for precision machining parts. By harnessing China's technical expertise, production efficiency, and quality assurance practices, businesses can achieve superior results and unlock new opportunities for growth and innovation. The success stories of companies collaborating with Chinese suppliers underscore the strategic advantages of leveraging China's precision machining capabilities to drive business success and competitiveness in the global market.

Conclusion: Harnessing the Potential of China Precision Machining Parts

In conclusion, China's precision machining industry offers businesses a wealth of opportunities to access high-quality, cost-effective parts that meet their specific needs and requirements. By tapping into China's vast manufacturing capabilities, advanced technologies, and skilled workforce, businesses can unleash the power of precision machining and elevate their production processes to new heights. From automotive and aerospace to medical and electronics industries, China's precision machining sector caters to a diverse range of applications and sectors, delivering parts that meet the highest standards of quality and performance.

While there are challenges and considerations to navigate when dealing with China in precision machining, the benefits far outweigh the risks. By partnering with reliable and reputable suppliers, implementing robust quality control measures, and leveraging the cost advantages of the Chinese market, businesses can optimize their supply chain and manufacturing operations for greater efficiency and competitiveness. The success stories of companies that have embraced China's precision machining capabilities serve as a testament to the transformative impact that Chinese manufacturers can have on businesses seeking to thrive in today's fast-paced and demanding market landscape